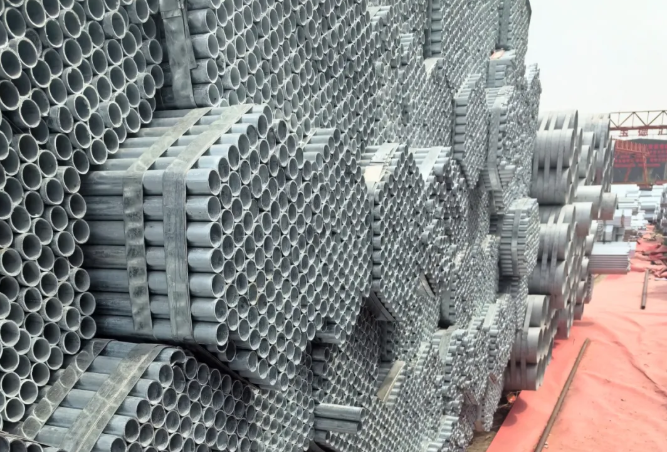

Dimensional Tolerances of Galvanized Steel Pipes (GB/T Standards)

Chinese national standard galvanized steel pipes are widely used in building structures, pipeline engineering, and machinery manufacturing due to their excellent corrosion resistance and mechanical strength. Their dimensional tole...

2026-01-21

China's crude steel output reached 960 million tons in 2025, a year-on-year decrease of 4.4%.

On January 19, the National Bureau of Statistics released a report titled "China's Industrial Value Added Increased by 5.2% in December 2025."The report shows that in 2025, China's crude steel output was 960.81 m...

2026-01-19

Thick-walled stainless steel seamless pipe

Thick-walled stainless steel seamless tubes are a type of pipe formed in one piece through processes such as hot rolling or cold drawing. They are named for their significant wall thickness and seamless construction. As a stainles...

2026-01-13

Henan Iron and Steel Successfully Rolls Three-Layer Stainless Steel Composite Plate

Recently, the Second Rolling Mill Department at the Anyang Base of Henan Iron and Steel Group successfully achieved stable rolling of 304FH32 triple-layer stainless steel composite plates with a thickness of just 3 millimeters on ...

2026-01-09

How to Assess the Quality of Polyurethane Insulated Pipes?

The quality of polyurethane insulated pipes directly impacts the safety, energy efficiency, and service life of the entire piping system. During actual procurement and acceptance processes, comprehensive evaluation must be conduct...

2026-01-07

High-Strength Seismic Rebar: 500 Reinforcing Steel

Internationally recognized Grade 500 reinforcing bars (such as ASTM A706 Grade 500 and Eurocode B500C) are highly consistent with China's HRB500E reinforcing bars in core performance characteristics (high strength, high ductil...

2026-01-04