Dimensional Tolerances of Galvanized Steel Pipes (GB/T Standards)

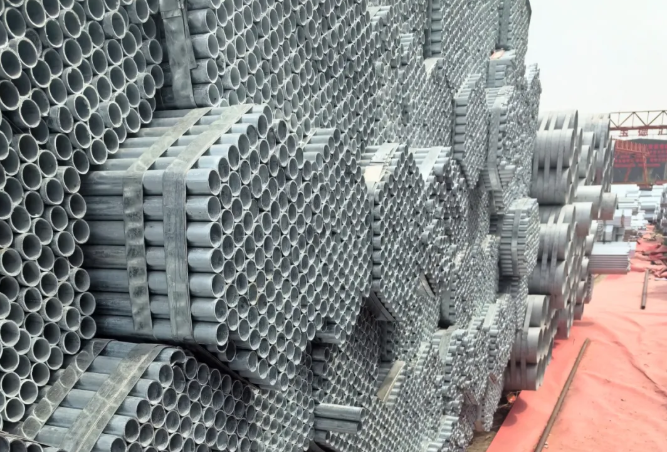

Chinese national standard galvanized steel pipes are widely used in building structures, pipeline engineering, and machinery manufacturing due to their excellent corrosion resistance and mechanical strength. Their dimensional tolerances, as the fundamental basis for measuring product quality, directly affect the accuracy of construction coordination and the overall safety of the project. Understanding and adhering to relevant tolerance standards is an important prerequisite for ensuring material quality and the smooth implementation of the project.

The dimensional tolerance requirements for galvanized steel pipes in China are mainly based on the relevant provisions of national standards GB/T 3091-2015 "Welded Steel Pipes for Low-Pressure Fluid Transportation" and GB/T 13793-2016 "Straight Seam Electric Welded Steel Pipes". These standards clearly define the permissible deviations of the main geometric dimensions of the finished galvanized pipes—outer diameter and wall thickness. Their technical specifications are consistent with widely recognized international standards such as ASTM A53 and EN 10255.

For outer diameter tolerances, they are generally classified according to the nominal outer diameter range. For common small-diameter pipes (e.g., outer diameter not exceeding 50 mm), the permissible deviation is typically ±0.5 mm. As the diameter increases, the permissible deviation also increases accordingly. For example, the deviation for medium-diameter pipes may be ±0.75 mm to ±1.5 mm, while the deviation for larger-diameter pipes is often controlled at ±1% of the outer diameter. This classification takes into account both the actual fluctuations in manufacturing processes and the actual precision requirements of different application scenarios.

Wall thickness tolerance is closely related to the nominal wall thickness. Generally, for thinner pipe walls (e.g., no more than 3 mm), the allowable deviation is approximately ±0.15 mm or ±10%. As the wall thickness increases, the absolute value of the allowable deviation becomes more lenient, but the relative percentage requirements may be more stringent. It is important to note that these tolerance requirements primarily apply to the base pipe (black pipe) before galvanizing. The galvanized layer itself also increases in thickness (the standard requires an average thickness of no less than 65 micrometers). Therefore, the overall dimensions of the final product must still meet assembly and usage requirements, taking into account the galvanized layer.

Setting reasonable positive and negative tolerances is not only a scientific way to accommodate fluctuations in production processes, but also a necessary design element to ensure the feasibility of engineering installation. If dimensions exceed the allowable range, it will directly lead to a series of problems such as loose pipe connections, uneven structural strength, and decreased system performance, and may even create safety hazards. Therefore, during project procurement and acceptance, the outer diameter and wall thickness of pipes must be strictly tested according to standards.

In engineering practice, construction and supervision units should use professional measuring tools for sampling measurements and pay attention to the uniformity of the galvanized layer and the overall material report. Meanwhile, selecting qualified suppliers with a complete quality system is key to controlling product quality from the source. Only by strictly adhering to tolerance standards can galvanized steel pipes ensure their proper performance in various engineering projects, guaranteeing the overall quality, safety, and long-term operation of the project.