What grade is A335 material?

A335 material is a low alloy steel and alloy steel seamless pipe widely used in high temperature and high pressure environments. It is mainly used in industries such as power, oil and gas, especially suitable for boilers, heat exchangers and piping systems.

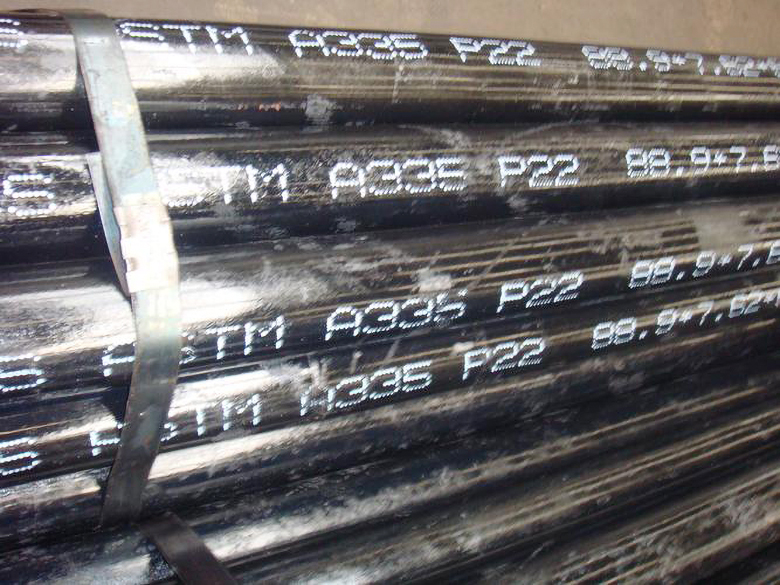

ASTM A335 includes multiple grades, the most common ones are P1, P5, P9, P11, P22 and P91. The difference between these grades is mainly in chemical composition and mechanical properties to meet different high temperature and high pressure application requirements.

ASTM A335 Steel Pipe Chemical Composition:

Material | C | Si | Mn | Mo | Cr |

A335 P1 | 0.30-0.60% | 0.50-0.80% | 0.30-0.60% | 0.44-0.65% | 0.90-1.20% |

A335 P5 | 0.15-0.25% | 0.50-0.80% | 0.30-0.60% | 0.45-0.65% | 4.00-4.50% |

A335 P9 | 0.05-0.15% | 0.50-0.80% | 0.30-0.60% | 0.90-1.10% | 8.00-9.00% |

A335 P11 | 0.05-0.15% | 0.50-0.80% | 0.30-0.60% | 0.44-0.65% | 1.00-1.20% |

A335 P22 | 0.05-0.15% | 0.50-0.80% | 0.30-0.60% | 0.90-1.10% | 1.90-2.60% |

ASTM A335 Steel Pipe Mechanical Properties:

Material | Tensile strength | Yield Strength | Elongation |

A335 Grade P1 | Min380 | 205 | 30 |

A335 Grade P5 | Min415 | 205 | 20 |

A335 Grade P9 | Min415 | 205 | 20 |

A335 Grade P11 | Min415 | 205 | 20 |

A335 Grade P22 | Min415 | 205 | 20 |