A third-party inspection agency conducted pre-shipment inspection on a batch of API 5L X52 seamless steel pipes from Yangtze Steel.

Recently, Yangtze Steel Group welcomed an authoritative third-party inspection team dispatched by a key international client to conduct final pre-shipment inspections on a batch of API 5L X52 carbon steel seamless pipes ordered by the client. The successful completion of this inspection not only reaffirms the exceptional stability and consistency of Yangtze Steel's products but also underscores the company's growing trust and professional reputation in the international market.

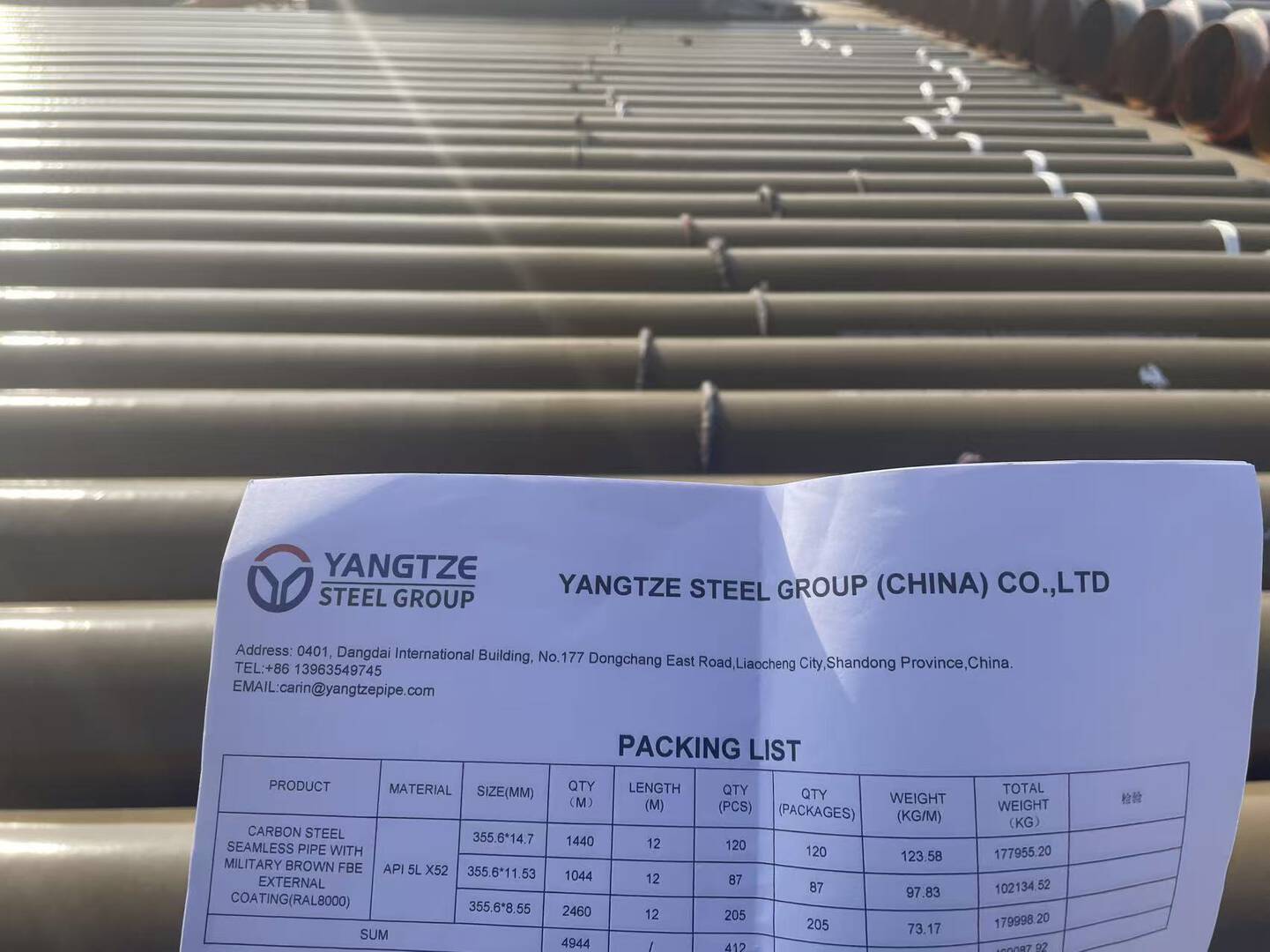

The core products inspected were high-standard API 5L X52 seamless steel pipes, widely used in critical applications such as oil and gas transportation and structural support. As per client specifications, these pipes were finished with a high-quality brown fusion-bonded epoxy (FBE) powder coating. This coating significantly enhances corrosion resistance and extends service life in harsh environments.

During the inspection, senior engineers from the third-party inspection company adhered to principles of independence, objectivity, and professionalism. They conducted a multidimensional, comprehensive assessment of the steel pipes based on relevant international standards such as API 5L and the client's specific technical requirements:

Dimension and Appearance Inspection: Precisely measure the outer diameter, wall thickness, length, and straightness of steel pipes to ensure full compliance with tolerance ranges; meticulously inspect the uniformity, adhesion, and integrity of the pipe surface and FBE coating, ensuring no defects.

Material and Performance Documentation Review: Strictly verified the Material Test Certificate (MTC) for each batch of steel, ensuring its chemical composition and mechanical properties (such as yield strength, tensile strength, etc.) meet the stringent API 5L X52 standards.

Coating Quality Testing: Conducted multiple critical performance tests on the FBE coating, including thickness measurement and adhesion testing, with results exceeding specification requirements.

Packaging and Marking Verification: Final product packaging was robust and reliable for long-distance ocean transport; spray-painted markings were clear and accurate, facilitating customer receipt and subsequent use.

Engaging an independent third-party for inspection is a common practice in modern international trade, reflecting the buyer's rigorous approach and safeguarding their interests. Yangtze Steel fully understands and welcomes this practice, providing comprehensive and transparent cooperation throughout this inspection.

"We firmly believe that quality is the cornerstone of earning respect, and transparency is the bridge to building trust," stated the head of Yangtze Steel's International Sales Department. "We welcome every customer, including their designated third-party representatives, to witness our manufacturing capabilities and quality control firsthand. This successful inspection not only serves as another strong endorsement of our API 5L X52 seamless steel pipe product quality but also marks a crucial step in establishing long-term, stable partnerships with our clients."

Yangtze Steel will continue to uphold its core values of "Quality First, Customer Foremost," continuously optimizing production processes and strengthening quality management. With an increasingly open and professional approach, we are committed to serving global customers and becoming an indispensable, trusted, and robust link in the international supply chain.