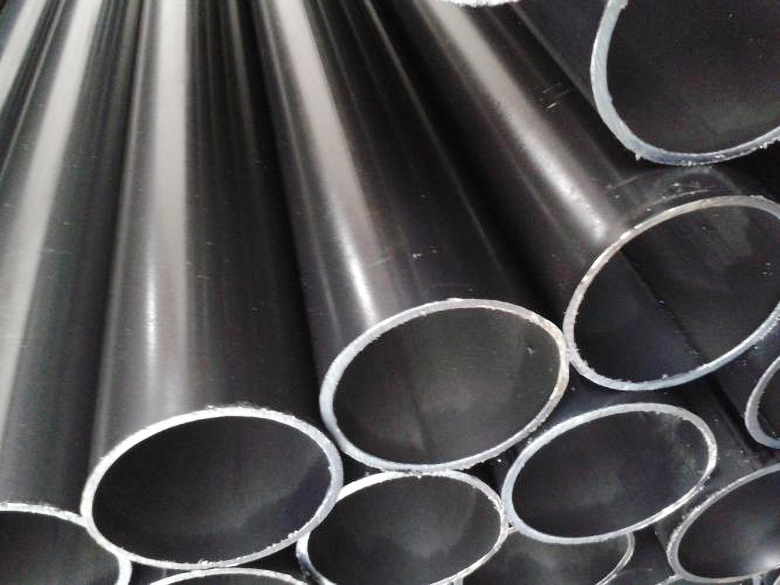

Black steel pipe detection method

Due to its excellent strength and corrosion resistance, black steel pipe is widely used in construction, petroleum, chemical and other industries. In order to ensure quality, the detection method is crucial. The following are common detection methods:

1. Appearance detection

Visually check whether there are obvious defects such as cracks, dents, rust, etc. on the surface to quickly identify problems.

2. Dimension measurement

Use calipers and thickness gauges to measure the outer diameter, wall thickness and length to ensure compliance with standards.

3. Non-destructive testing

① Ultrasonic testing: Identify internal defects.

② Radiographic testing: Check the internal quality of welds.

③ Magnetic particle testing: Identify surface and near-surface defects.

4. Chemical composition analysis

Sampling analysis to ensure that the material meets the standards, commonly used spectral and chemical analysis.

5. Tensile test

Determine the tensile strength and yield strength, and evaluate the bearing capacity and toughness.

6. Hydrostatic test

Detect the sealing and pressure resistance of the pipeline under high pressure to ensure no leakage or deformation.

Conclusion

Through these detection methods, the quality of black steel pipes can be comprehensively evaluated to ensure safe use in engineering. Regular inspection and maintenance can help extend the life of your black steel pipe and improve overall safety.