What is HSAW steel pipe?

HSAW steel pipe (Helical Submerged Arc Welded Pipe) is a kind of steel pipe that is made by rolling a steel strip into a tube in a spiral shape and then welding it using submerged arc welding technology.

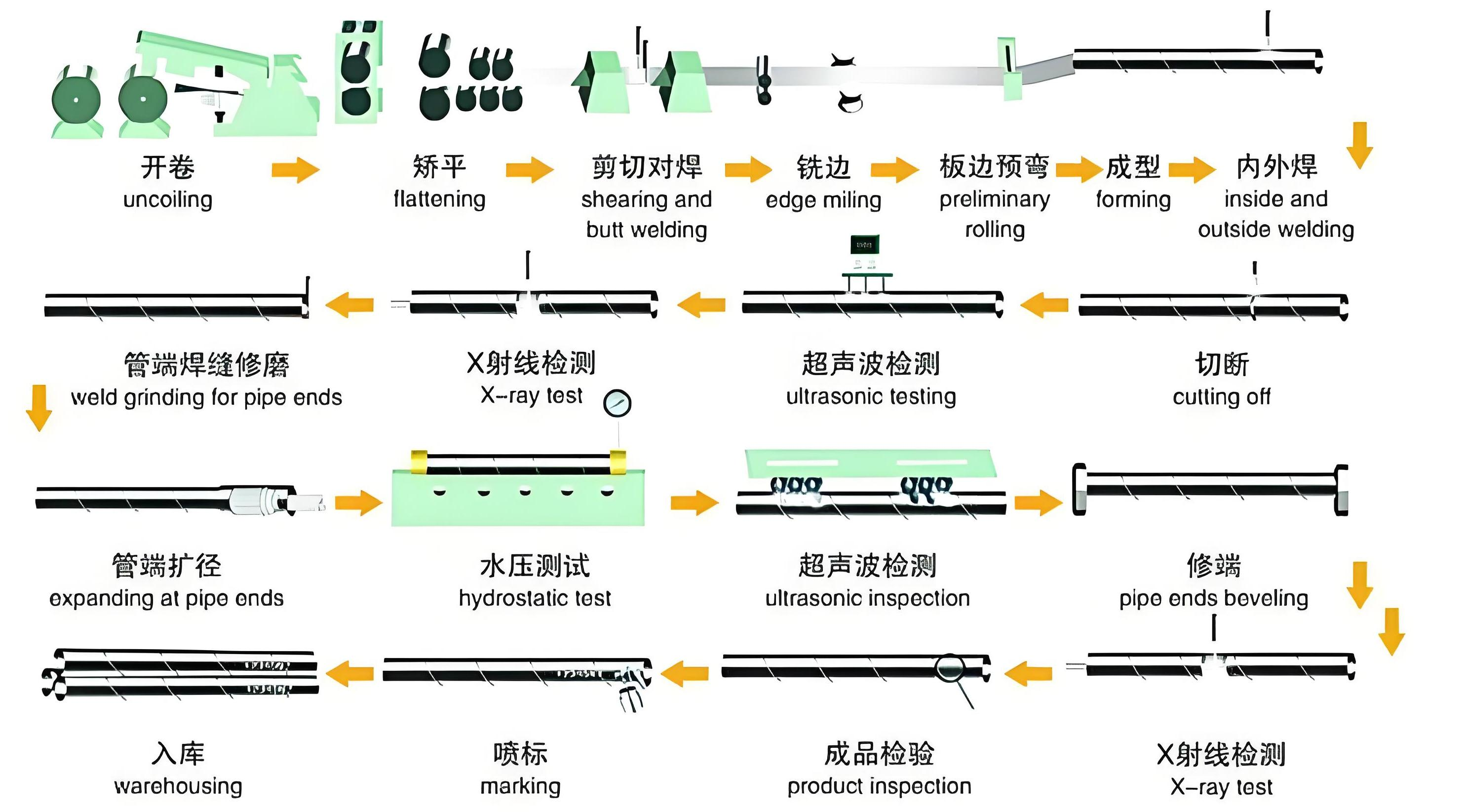

HSAW manufacturing process

Features of HSAW steel pipe

1. High strength: The weld is spirally distributed, and the pressure resistance is stronger than that of straight seam welded pipe.

2. Large diameter production: suitable for pipeline projects from 300mm to 3000mm.

3. Stable welding quality: Submerged arc welding is anti-oxidation, and the weld has uniform strength and high strength.

4. High cost-effectiveness: The process is simple, especially suitable for large-diameter and long-distance pipeline projects.

Production standards

The production of HSAW steel pipes must comply with a number of international standards, such as:

1. API 5L: used for oil and gas pipelines.

2. ISO 3183: International standard for oil and gas pipelines.

3.EN 10217: Standard for spiral welded steel pipes for pressure pipelines.

In short, HSAW steel pipes have become the preferred material for long-distance transmission pipelines and large engineering projects due to their high strength, low cost and large diameter production capabilities.