What is DSAW steel pipe?

DSAW (Double Submerged Arc Welded) pipe is a steel pipe manufactured by double-sided submerged arc welding process. Due to its high strength and superior weld quality, it is widely used in oil, natural gas, water pipelines and other fields.

1. Manufacturing process

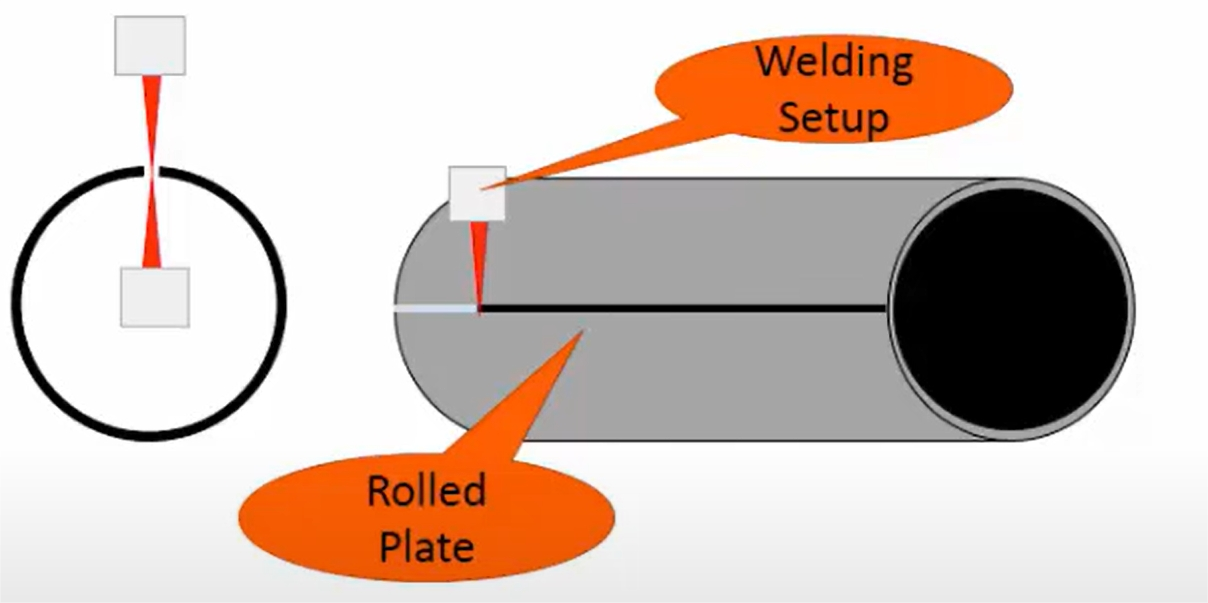

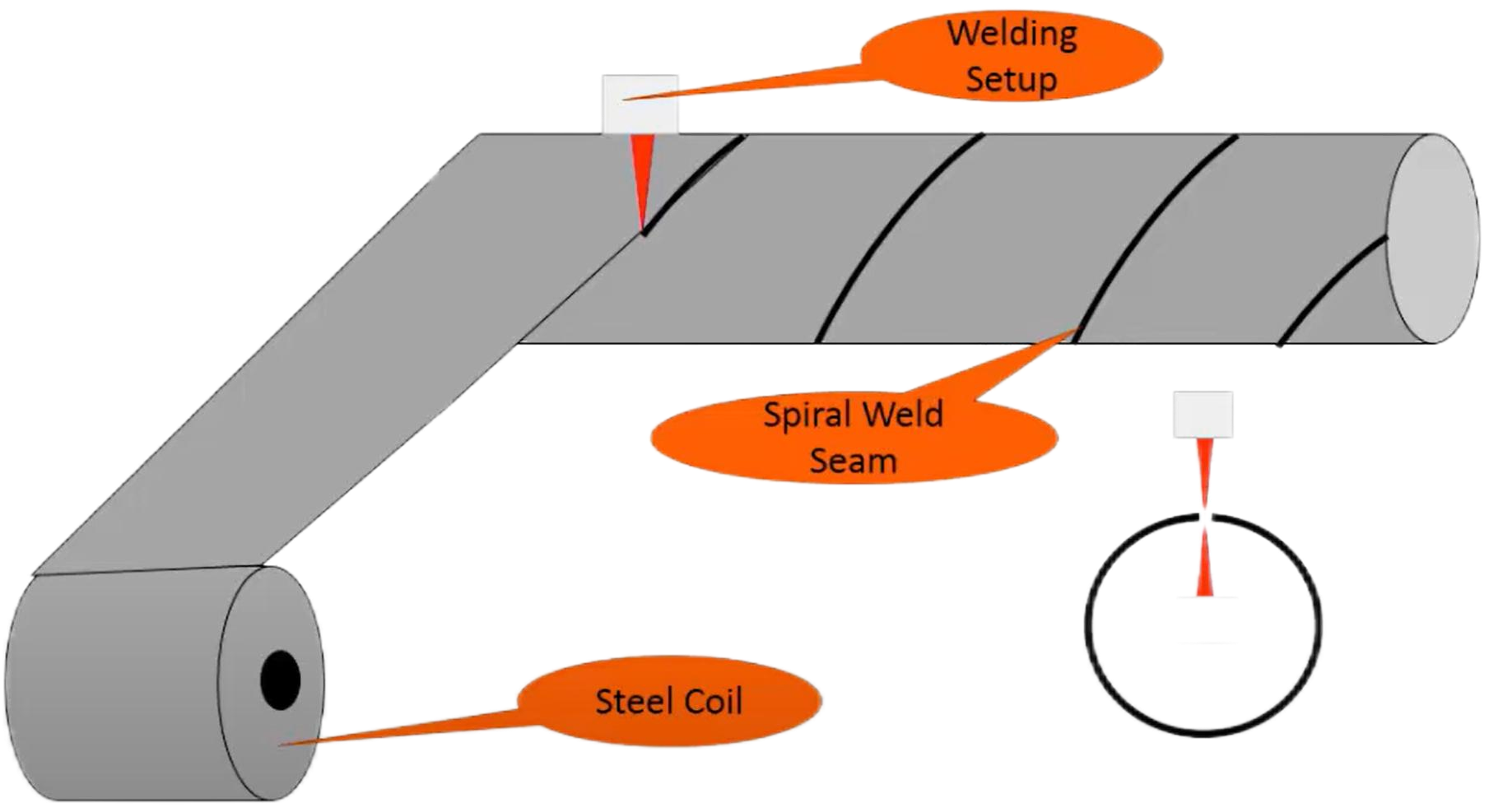

Depending on the welding method, it is divided into two forms: straight seam welding (LSAW) and spiral welding (SSAW).

DSAW straight seam steel pipe welding schematic

DSAW spiral steel pipe welding schematic

The following is the process flow of DSAW steel pipe in the actual production process (taking straight seam as an example):

2. Comparison of straight seam and spiral welding

Project | LSAW | SSAW |

Weld length | Short weld | Longer weld |

Production efficiency | High welding difficulty, | Higher production efficiency, |

Applicable pressure | Suitable for high pressure and | Applicable to medium and |

Pipe diameter range | Commonly used for large diameter | Can be used for large diameter |

Cost | Relatively high | Lower cost |

3. Specifications and standards

Parameters | Range or standard |

Diameter | 16 inches-60 inches (406mm-1524mm) |

Wall thickness | 6mm-40mm |

Common standards | API 5L (oil and gas pipeline standard), ISO 3183, ASTM A139, etc. |

DSAW pipe's double-sided welding technology ensures its reliability and durability in high pressure and corrosive environments, and is the preferred material in important pipeline transportation projects such as oil and natural gas.