Three connection methods of spiral steel pipes

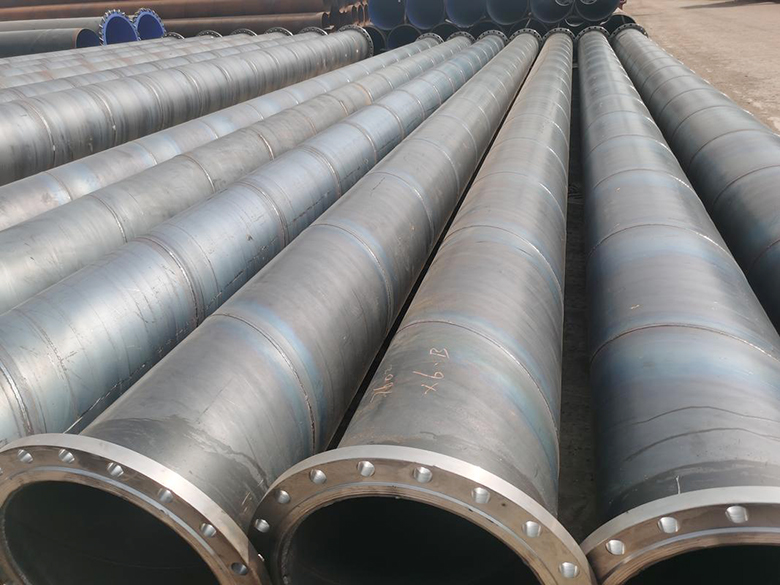

Spiral steel pipes are widely used in construction, petroleum, chemical and other industries. The choice of its connection method is crucial to the stability and service life of the pipeline system. The three common connection methods are welding connection, flange connection and socket connection. Each method has different applicable occasions and characteristics.

1. Welding connection

Welding connection is to fuse the two ends of the pipe together through welding equipment to form a firm joint. It has high strength and good sealing, suitable for high-pressure and high-temperature projects.

2. Flange connection

Flange connection fixes two pipes together through flanges and bolts, and uses sealing gaskets to prevent leakage. It is suitable for occasions that require frequent disassembly and maintenance, and is easy to install.

3. Socket connection

Socket connection is to insert one pipe into the socket of another pipe and then seal it with sealing material. It is often used in small-diameter, low-pressure pipeline systems. The construction is simple and suitable for water supply and drainage systems.

Reasonable selection of connection methods according to project requirements can effectively improve the reliability and applicability of spiral steel pipe systems.