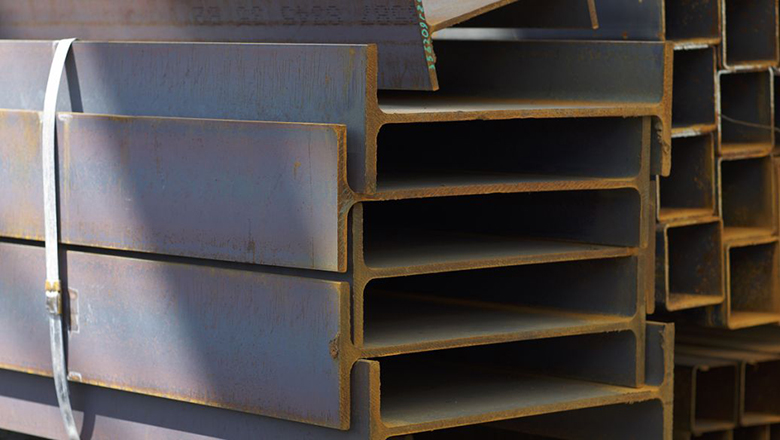

Hot-rolled and welded H-beam

H-beam is an important structural material widely used in construction and engineering. According to different production processes, H-beam can be divided into hot-rolled H-beam and welded H-beam.

1. Hot-rolled H-beam

Features

Hot-rolled H-beam is formed by heating raw materials and rolling, and has high strength and toughness.

2. Welded H-beam

Features

Welded H-beam is assembled by welding after cutting steel plates, and has high flexibility and customization.

Features | Hot-rolled H-beam | Welded H-beam |

Production process | Hot-rolled | Steel plate welding assembly |

Strength | High strength, high toughness | Adjustable strength, depending on |

Dimensional accuracy | High precision, standardized production | Can be customized according to needs |

Applicable scenarios | High-rise buildings, bridges, | Lightweight construction, special design |

Cost | Strong economic efficiency, suitable | Higher cost, suitable for small batches |

Construction speed | Requires on-site processing, slow | Can be made in advance, faster construction |

Hot-rolled H-beam and welded H-beam have their own advantages and disadvantages. Hot-rolled H-beam is suitable for structures with heavy loads, while welded H-beam is more flexible and suitable for customized design. Choosing the appropriate type of H-beam according to specific project needs and budget can ensure the safety and economy of the project.