Cold-rolled stainless steel plate

Cold-rolled stainless steel plate is a type of stainless steel plate produced by a cold rolling process at room temperature. Compared with hot-rolled stainless steel plate, cold-rolled stainless steel plate has higher precision and better surface quality.

Manufacturing process

1. Hot rolling and pickling: The stainless steel billet is first hot-rolled into thick plates or strips, and then pickled to remove the oxide scale and impurities on the surface.

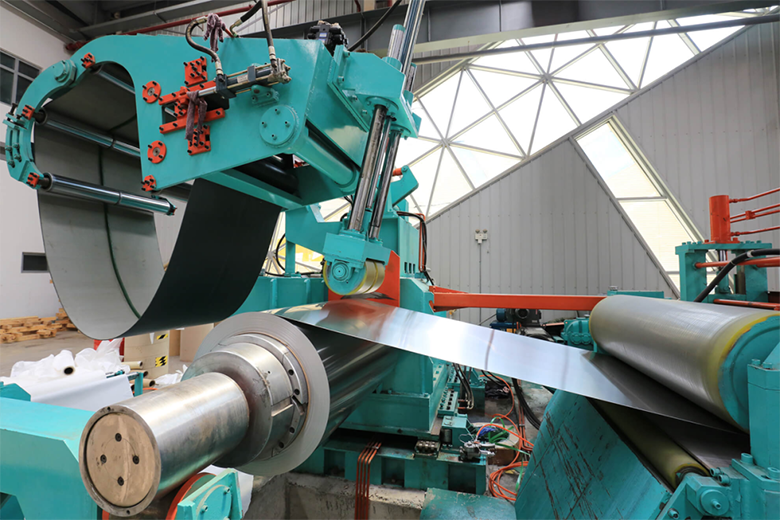

2. Cold rolling: At room temperature, the pickled stainless steel strip is gradually reduced in thickness through multiple cold rolling. This process improves the surface finish and dimensional accuracy of stainless steel.

3. Annealing and pickling: After cold rolling, stainless steel usually needs to be annealed to eliminate work hardening and improve ductility. Then pickling is performed to further clean the surface.

4. Surface treatment:

Depending on the end use, the surface of stainless steel can be polished, brushed or otherwise treated to improve its decorative properties and corrosion resistance.

Common types and specifications

Common ones include austenitic stainless steel (such as 304, 316), ferritic stainless steel (such as 430), martensitic stainless steel (such as 410), etc. The common thickness ranges from 0.3mm to 6mm, and the width ranges from 1000mm to 2000mm, which can be customized according to different needs.