How to identify the quality of anti-corrosion steel pipes?

Identifying the quality of anti-corrosion steel pipes is essential to ensure their reliability and long life during use. Here are some methods and key points.

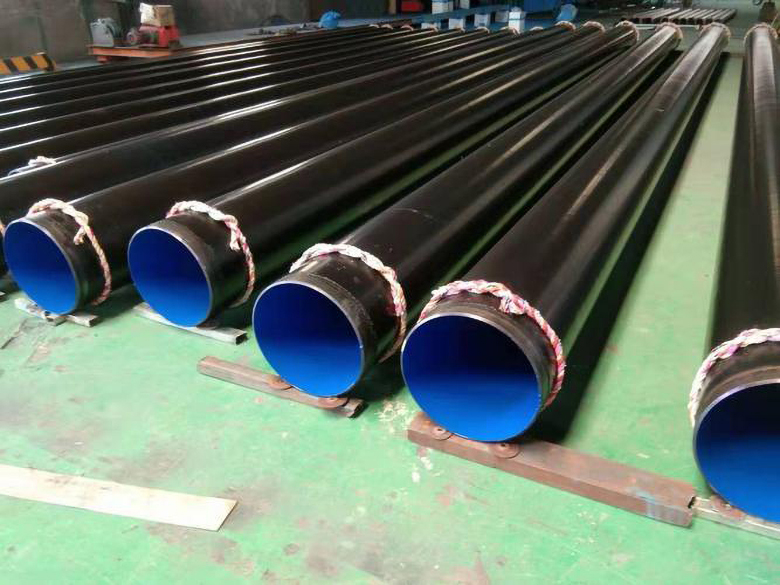

Appearance inspection:

1. Check whether the surface of the anti-corrosion layer is uniform and free of defects, such as bubbles, cracks, and peeling.

2. Ensure that the color is consistent and there is no obvious color difference.

Thickness measurement:

Use a coating thickness gauge to measure the thickness of the anti-corrosion layer to ensure that it meets the standard requirements.

Material inspection:

1. Check the quality certificate of the anti-corrosion coating material to ensure that it meets the relevant standards.

2. Verify the inspection report of the steel pipe material to ensure that its chemical composition and mechanical properties meet the standards.

Construction process:

Ensure that the anti-corrosion construction process meets the specifications, including surface pretreatment, coating application and curing steps.

Quality certification:

1. Third-party testing: Check whether there is a quality inspection report issued by a third-party testing agency to ensure that the product quality meets the relevant standards.

2. Relevant certification: Confirm whether the anti-corrosion steel pipe has passed relevant quality certifications, such as ISO certification, etc.

Through the inspection and testing in the above aspects, the quality of anti-corrosion steel pipes can be identified more comprehensively to ensure their reliability and long life during use.