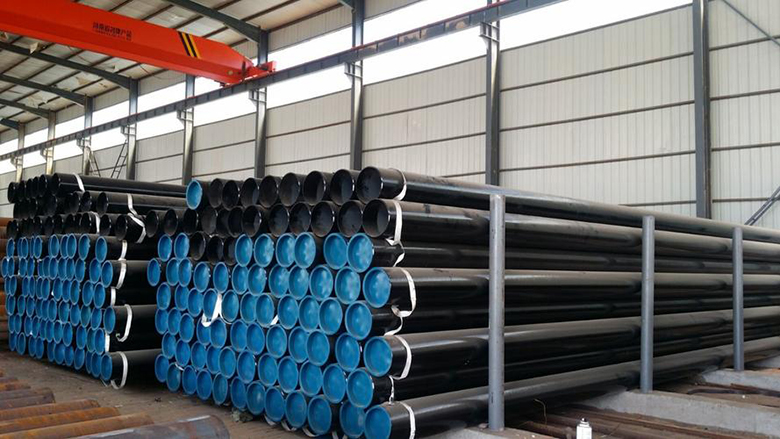

Production process of black low carbon steel pipe

As a material widely used in industry, the production process of black low carbon steel pipe is crucial and directly affects the quality and performance of steel pipe.

1. Raw material preparation

After the low carbon steel plate is cut into a slab of appropriate size, it is rust-removed and surface-treated to remove oxides and impurities, providing good conditions for subsequent processing.

2. Steel pipe rolling

The steel billet is heated to an appropriate temperature, and after multiple passes of rolling and stretching, it gradually forms a tube shape. It is necessary to control the size and wall thickness of the tube, and regularly maintain and replace the rollers.

3. Welding

The rolled steel plates are connected together, which are divided into long welding and spiral welding. Choose appropriate welding methods and materials to ensure the quality and strength of the weld.

4. Heat treatment

Through annealing, normalizing, quenching and other processes to improve the organization and performance of the steel pipe, and enhance plasticity, toughness and strength.

5. Other processes

Includes pickling, cutting, forming and surface treatment. Pickling removes oxides and rust, cutting into the required length, forming by a forming machine, and surface treatment to improve corrosion resistance.

Through reasonable process and strict quality control, we can produce high-quality low-carbon steel pipes to meet the needs of various industries.