Characteristics of thermal insulation performance of anti-corrosion pipelines

The characteristics of thermal insulation performance of anti-corrosion pipelines are mainly reflected in the following aspects:

First, it is reflected in its strong anti-corrosion ability.

These pipelines have formed a solid anti-corrosion layer by adopting advanced anti-corrosion technologies, such as spraying epoxy resin, hot-dip galvanizing, etc., which can effectively resist the erosion of corrosive media such as acids, alkalis, and salts, thereby greatly extending the service life of the pipeline.

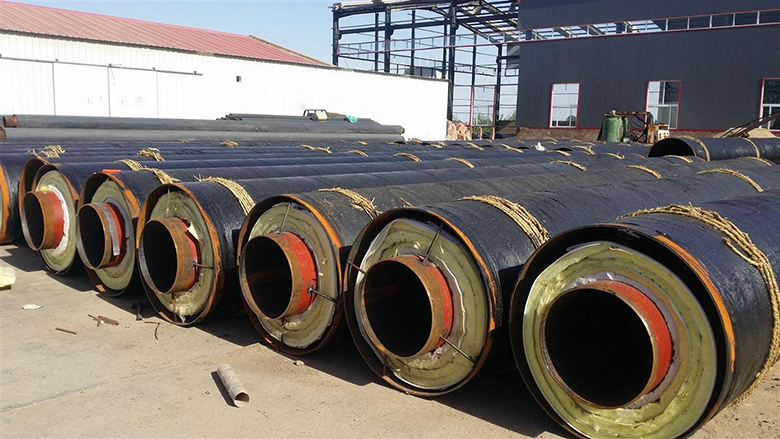

Secondly, anti-corrosion pipelines also have excellent thermal insulation performance.

By adding high-quality thermal insulation materials, such as polyurethane foam and rock wool, these materials have extremely low thermal conductivity, which can effectively reduce the heat loss of the pipeline during the transmission of the medium and maintain the stability of the medium temperature in the pipeline. This not only improves energy utilization efficiency, but also reduces operating costs.

In addition, the anti-corrosion pipeline insulation system also has the advantages of simple construction and convenient maintenance.

Its prefabricated and modular design makes installation faster and more convenient, reducing the construction period. At the same time, its high-quality anti-corrosion layer and thermal insulation layer also reduce the frequency of pipeline damage and repair, and reduce maintenance costs.