ERW steel pipe process performance inspection standard

ERW pipe process performance inspection:

1. Raw material inspection: First, the chemical composition, mechanical properties and surface quality of the raw material steel strip or steel coil are inspected to ensure that the raw material quality meets the production requirements.

2. Weld quality inspection: Through non-destructive testing methods such as ultrasonic testing and radiographic testing, the weld is internally inspected to ensure that the weld is free of cracks, unfused and other defects.

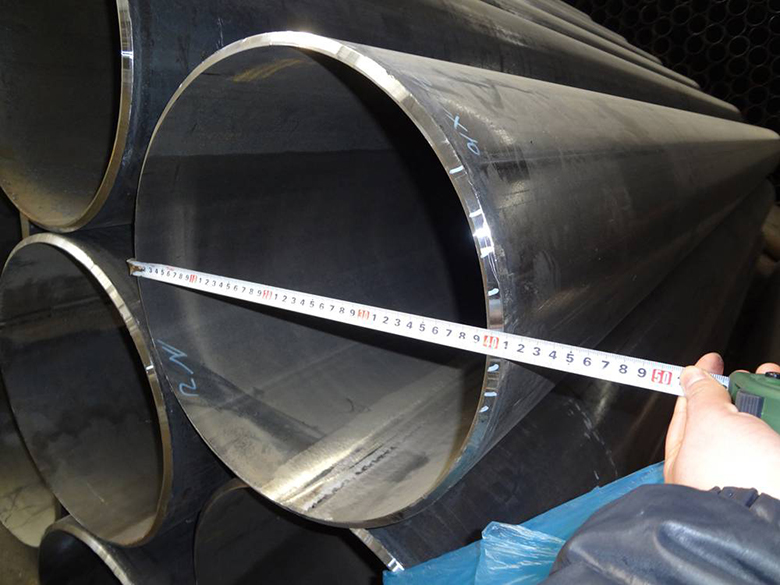

3. Size and shape inspection: Check the dimensional parameters such as the outer diameter, wall thickness, and ovality of the ERW pipe to ensure that it meets the relevant standards or customer requirements.

4. Mechanical property test: Conduct tensile, flattening, flaring and other tests to evaluate the mechanical properties of the ERW pipe, such as yield strength and tensile strength. For example, in the flattening test, when the ERW pipe is pressed to 3/4 of the diameter, observe whether the weld cracks.

5. Surface quality inspection: Check whether the surface of the ERW pipe is smooth, free of rust, scratches and other defects to ensure that the appearance quality meets the requirements.

6. Water or air pressure test: Check the sealing and pressure resistance of the ERW pipe by filling it with water or gas and applying pressure.

7. Packaging and labeling inspection: Finally, check the packaging and labeling information of the ERW pipe to ensure accuracy.