Process performance inspection standard for seamless steel pipes

(1) Hydraulic test: Pour water of a certain pressure into the steel pipe to be tested and maintain the pressure for a certain period of time (the test pressure value and the stabilization time are in accordance with the standard). There shall be no leakage. This test is a non-destructive test and is commonly used to inspect various products.

(2) Flattening test: Place the steel pipe sample between two flat clamps, apply force between the clamps until the distance reaches the standard value, and check that there shall be no defects such as cracks and fissures in the deformation area of the sample.

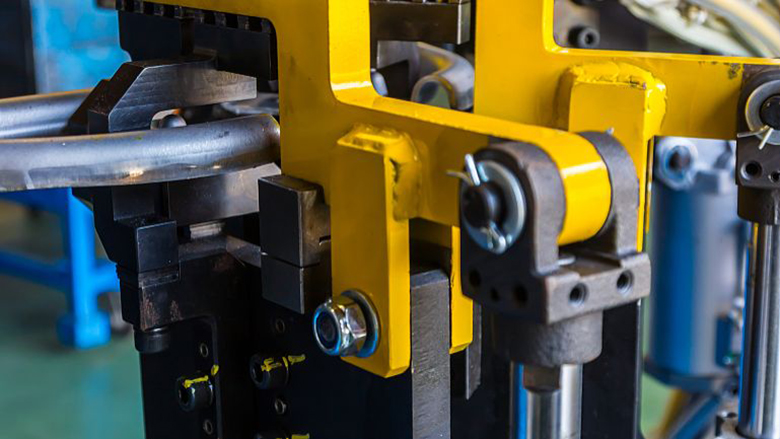

(3) Bending test: Place the steel pipe sample on a bending test machine and bend it to the angle required by the standard according to the bending core radius specified in the standard. There shall be no cracks and fissures on the surface of the bend.

(4) Expansion test: Place the steel pipe sample on a workbench with the opening facing up, and press the top selected according to the standard taper into the steel pipe until the expansion rate of the test outer diameter reaches the standard, and there shall be no defects such as cracks and fissures on the surface of the sample.