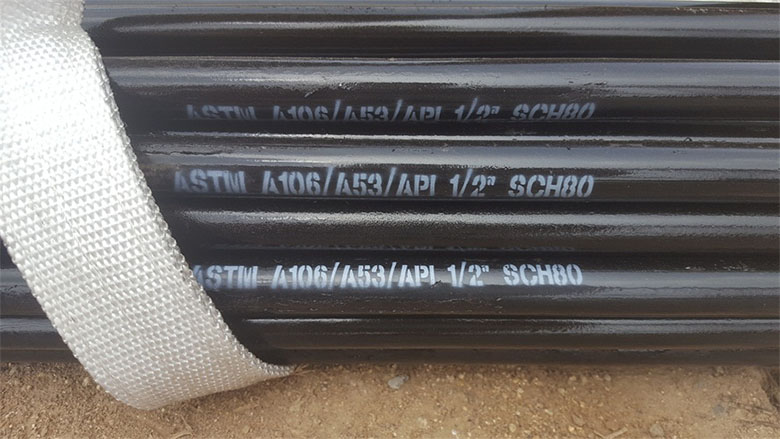

What is the difference between ASTM A106 pipe and ASTM A53 pipe?

ASTM A106 pipe and ASTM A53 pipe differ in many aspects, mainly including the following aspects:

1. Purpose and scope of application:

ASTM A53 pipe: This is a general-purpose non-seamless steel pipe standard commonly used for the transportation of fluids such as gas, water, steam and air. Its characteristics are that the steel pipe has a smooth surface, high dimensional accuracy and high tensile strength.

ASTM A106 pipe: It is a transmission pipeline standard suitable for high temperature and high pressure. It is suitable for three types of materials: A, B and C. A106 standard steel pipes are mainly used for the transportation of high-pressure heating equipment such as oil, natural gas, chemicals, etc. Its main advantages are that it has a stronger ability to withstand high pressure and will not undergo plastic deformation and rupture.

2. Performance characteristics:

ASTM A53 pipe: It has high strength and toughness and can withstand large pressure and tension, ensuring the safety and stability of the pipeline system. In addition, it also has good wear resistance and impact resistance, which can effectively extend the service life of the pipeline.

ASTM A106 pipe: It can still maintain excellent performance at high temperatures, and the maximum service temperature can reach 600°C. At the same time, it has good corrosion resistance to most chemicals and can be widely used in various corrosive environments. In addition, ASTM A106 pipe also has the characteristics of seamless structure, high dimensional accuracy, smooth surface, etc., and is easy to clean and maintain.

3. Manufacturing process:

ASTM A106 pipe adopts advanced manufacturing technology, including material selection, heat processing and heat treatment. Among them, high-quality carbon steel materials are used in the material selection stage to ensure that the chemical composition and mechanical properties of the steel pipes meet standard requirements. In the thermal processing stage, the pretreated steel is heated, and after reaching a certain temperature, it is hot extruded to form the preliminary embryo of the steel pipe. Finally, the mechanical properties and corrosion resistance of the steel pipe are improved through a heat treatment process.

In general, there are differences between ASTM A106 pipe and ASTM A53 pipe in terms of use, performance characteristics and manufacturing processes. The choice of pipe depends on the specific project needs and usage environment.