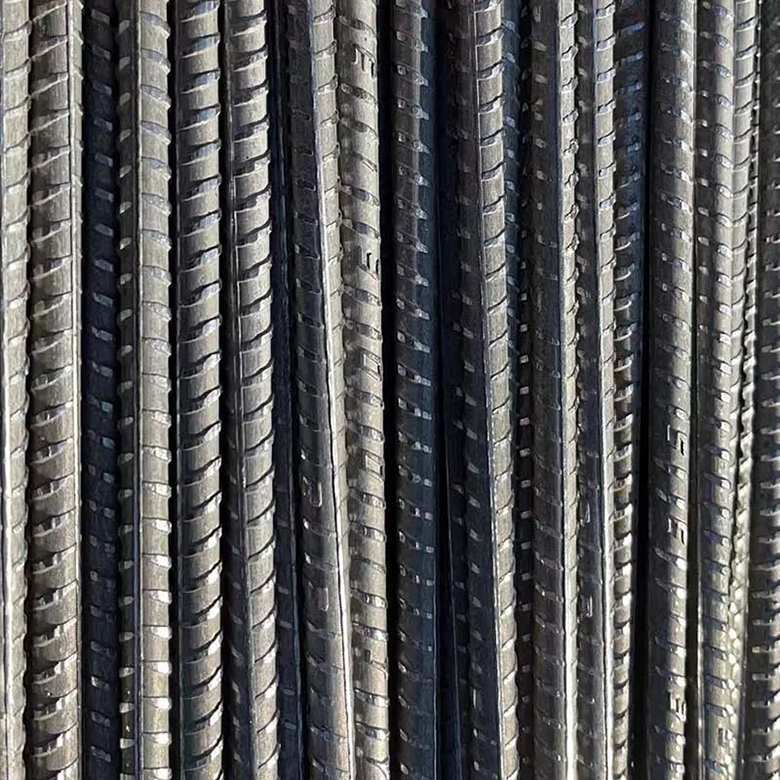

Rebar

Rebar is a type of steel with a threaded pattern, often used to strengthen concrete structures. Its surface usually has rough threads, which help the rebar to bond better with concrete and enhance the tensile properties of the concrete structure.

Features and Benefits

1. High strength: Rebar has higher strength than ordinary steel and can effectively strengthen the tensile properties of concrete structures.

2. Easy to construct: The bond between rebar and concrete is stronger and the construction process is simpler and more convenient.

3. Environmental protection: The use of rebar to reinforce concrete structures can reduce the use of materials, reduce resource consumption, and is beneficial to environmental protection.

Manufacturing process

Rebar is usually processed from ordinary round steel. The manufacturing process includes the following steps:

1. Cold rolling/hot rolling: Starting from the original steel billet, it can be rolled into round steel by cold rolling or hot rolling.

2. Cutting: The cutting machine cuts the rolled round steel into appropriate lengths.

3. Pretreatment: Before thread processing, round steel may require pickling or other pretreatment processes.

4. Thread processing: Round steel is threaded through a threading machine to form thread patterns on the surface.

5. Inspection and Packaging: After completing thread processing, the rebar will undergo quality inspection and be packaged and shipped as needed.Specifications and dimensions

Rebar gauges and dimensions are typically determined by diameter, length and thread type. Common diameters include 6mm, 8mm, 10mm, 12mm, etc., and the length is usually 6 meters or 12 meters.