Oil pipe manufacturing process

The manufacturing process of oil pipes involves multiple steps to ensure the production of high-quality pipes suitable for use in the oil and gas industry. The following is an overview of typical manufacturing processes.

1. Raw material selection:

The process begins with selecting a high-quality raw material (usually steel) that meets the required specifications for the tubing. Commonly used materials include carbon steel and various grades of alloy steel.

2. Pipe formation:

The selected steel is first heated to a ductile temperature and then formed into a cylindrical shape. This can be done via one of the following methods:

3. Seamless pipe manufacturing:

In this process, a solid cylindrical billet is perforated and elongated to form a seamless tube.

Welded pipe manufacturing: In this process, flat steel plates are rolled into a cylindrical shape and then welded longitudinally. Welded pipe is generally less expensive than seamless pipe.

4.Heat treatment:

After forming, the pipe may undergo a heat treatment process to improve its mechanical properties and eliminate residual stresses. This step usually involves annealing, quenching and tempering.

5. Size and size control:

The tubing is then passed through sizing rollers or dies to obtain the desired outer diameter and wall thickness. Precise dimensional control is critical to meeting industry standards and customer specifications.

6. Cutting and length control:

The tubing is cut to specified lengths and the ends are usually prepared for subsequent threading or joining.

7. Thread processing:

Most tubing requires threaded connections at both ends to allow for easy assembly and disassembly at the wellsite. Special machinery is used to cut threads in the pipe ends.

8. Inspection and testing:

Strict quality control and inspection procedures are implemented to ensure that pipes meet industry standards. This includes non-destructive testing methods such as ultrasonic testing, magnetic particle testing and visual inspection.

9. Surface treatment:

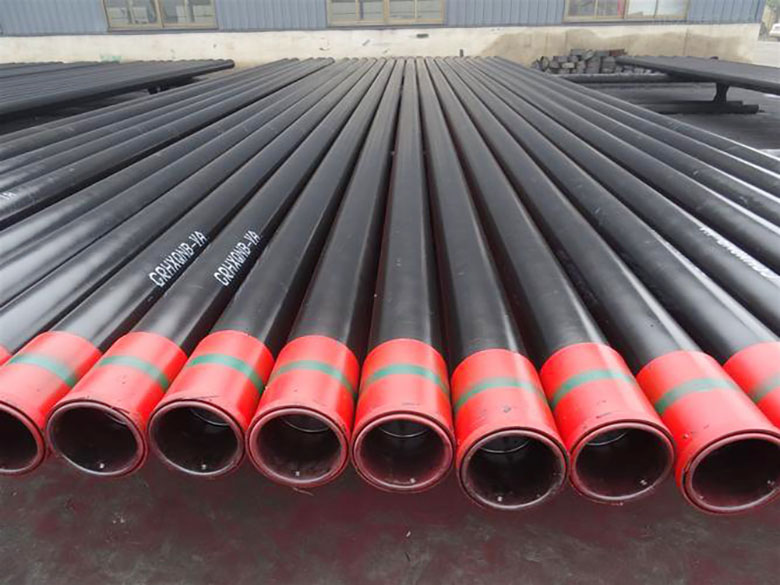

Pipes can have surface treatments, such as phosphate coatings or other protective coatings, to enhance corrosion resistance and extend the life of the pipe.

10. Marking and identification:

Each pipe is marked with basic information including size, material grade, heat number, manufacturer name or logo, and other required identifiers.

11. Packaging and transportation:

Product tubing is bundled, packaged and prepared for shipment to the oil field or customer site.