Polishing Method Of Seamless Steel Pipe

Stainless steel pipe is a long steel material with a hollow section and no seams around it. Its types are as follows:

Classified by manufacturing process:Stainless steel seamless pipe, stainless steel welded pipe, stainless steel cold drawn pipe, stainless steel cold expanded pipe.

Classification by material:Austenitic stainless steel pipes and ferritic stainless steel pipes.

Classified by specifications Including outer diameter, wall thickness, etc. Common specifications include Φ6, Φ8, Φ10, Φ12, Φ14, Φ16, Φ18, Φ20 and other stainless steel pipe outer diameters.

There are three polishing methods for seamless steel pipes:

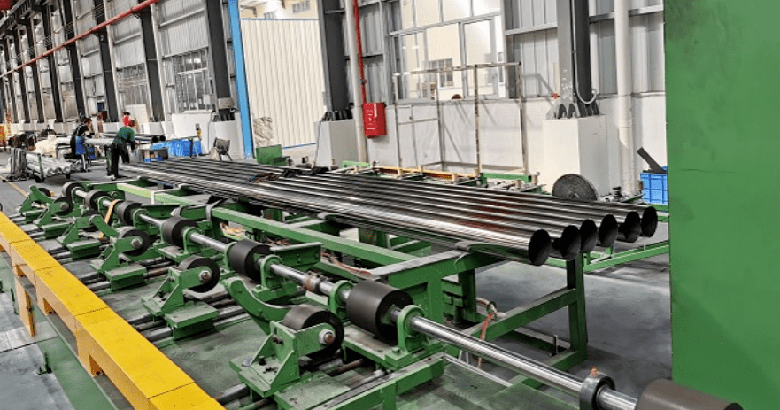

Mechanical polishing. Using mechanical equipment, such as a polishing machine or grinder, the seamless steel pipe is placed on the mechanical equipment for polishing. This method completes the polishing job quickly and efficiently, but may cause mechanical marks or scratches.

Chemical polishing. Polishing using chemicals such as pickling or electropolishing. This method can remove oxides or rust on the surface of seamless steel pipes, making the surface smoother. But you need to pay attention to safety.

Hand polished. Seamless steel pipe is hand polished using hand tools such as sandpaper or abrasive cloths. This method can adjust the degree of polishing as needed, but the workload is larger and the efficiency is lower.