Angle steel packaging inspection standards

Common packaging inspection standards for angle steel mainly include the following aspects:

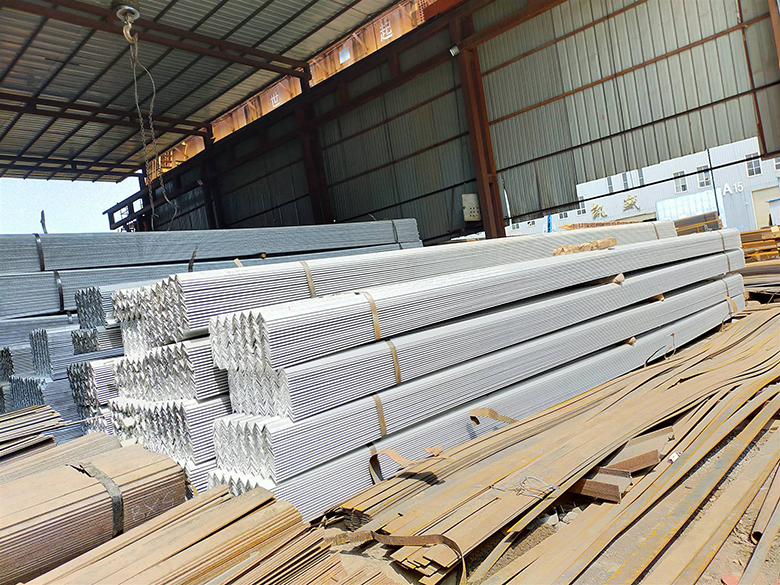

1. Packaging materials: Angle steel is generally delivered naked, but it is also necessary to consider the use of appropriate packaging materials, such as steel strips or galvanized iron wires, to ensure stability and safety during transportation and storage.

2. Packaging size and weight: The height of angle steel packaging should not exceed 500mm, the height-to-width ratio should be controlled at less than 1:2, and the packaging weight should be controlled at less than 3 tons. These regulations are intended to ensure packaging stability and ease of handling.

3. Bundling method: The steel strapping should be moderately tight, not only to ensure that the angle steel will not loosen or shift within the package, but also to avoid over-tightening that may cause deformation or damage to the angle steel.

4. Packaging identification: The finished product packaging should be clearly marked, including project name, product name, specifications and models, manufacturer and other information. The handwriting of the logo should be clear, and arbitrary alteration or omission of words should be prevented. In addition, the packaging should also have the code name of the person in charge of the packaging to facilitate tracking and inquiry.

It should be noted that specific packaging inspection standards may vary depending on different products, specifications and uses. Therefore, in actual operations, inspections should be carried out according to specific standards and specifications to ensure that the packaging of angle steel meets relevant requirements.