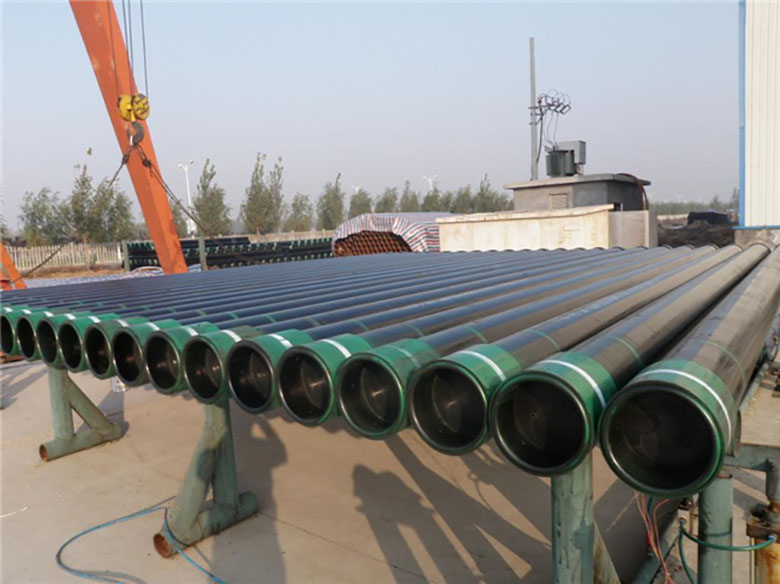

Oil casing specifications and performance characteristics

Oil casing is an indispensable and important equipment in oil drilling. It is mainly used to support the well wall during the drilling process to ensure the smooth progress of the drilling process and maintain the normal operation of the entire oil well after completion.

1. Specifications

The basic specifications of oil casing mainly include diameter, wall thickness, length and connection method:

Diameter: refers to the outer diameter of the oil casing, generally in inches. Common oil casing diameters are 4 1/2 inch, 5 inch, 5 1/2 inch, etc. There are also diameters specified according to API standards and national standards. For example, API standard oil casing specifications include outer diameter specifications such as 139.7, 177.8, and 244.5; national standard oil casing specifications include diameters of 48mm, 60mm, 73mm, 88.9mm, and 114.3mm. and 139.7mm and other different specifications.

Wall thickness: refers to the wall thickness of oil casing, generally in units of 1/10 inch (mill). Common oil casing wall thicknesses are 0.205 mill, 0.254 mill, 0.289 mill, etc. Among them, the wall thickness of oil casing with an outer diameter of 139.7mm is usually between 2.5 and 10mm.

Length: Generally about 31 meters, but it needs to be cut according to the well depth before use. There are also special lengths of oil casing, such as 6 meters, 12 meters, etc.

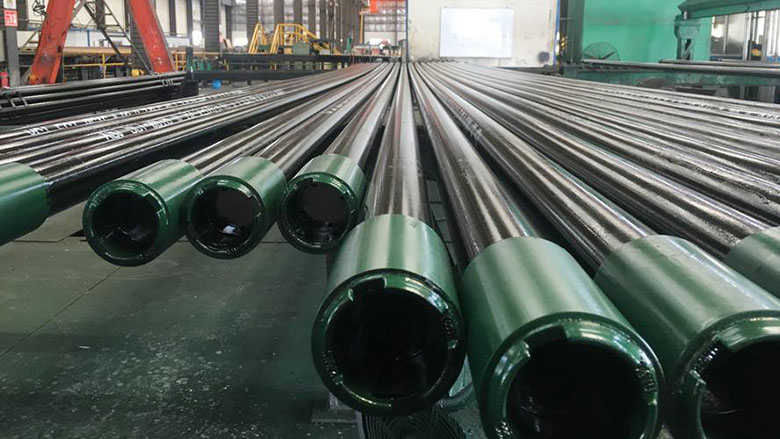

Connection method: The connection methods of oil and casing include external thread, internal thread and drill pipe joint, etc. Different connection methods are suitable for different working conditions and needs.

2. Performance characteristics

Oil casing products have the common advantages of ERW welded pipes and seamless pipes. Its performance characteristics mainly include the following aspects:

Strength: It has good tensile strength and yield strength and can withstand various loads during drilling. For example, K55 oil casing is made of high-quality steel and has high strength and good corrosion resistance, which can ensure safe use in oil and gas wells.

Precision and organization: The product has high dimensional accuracy and uniform organization.

Toughness: The product has good toughness and is conducive to adapting to various complex underground environments.

In addition, different types of oil casing have different steel grades, such as J55, K55, N80, Q125, Q130, Q140, etc., which are suitable for different working conditions and operating environments.