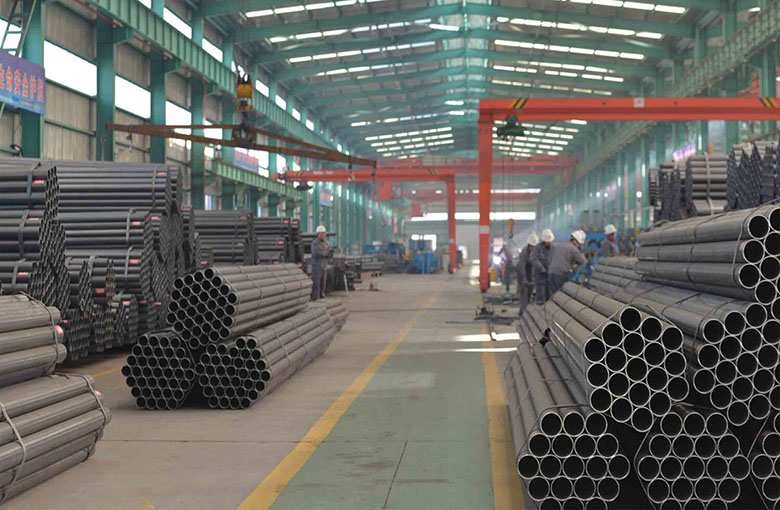

ERW Straight Seam Welded Pipe

ERW straight seam welded pipe, also known as electric resistance welded straight seam welded pipe, is a steel pipe manufactured by resistance welding process. This kind of steel pipe has high production efficiency, low cost, material saving, and is easy to realize automated production. According to the frequency, ERW straight seam welded pipe can be divided into low frequency welding, medium frequency welding, super medium frequency welding and high frequency welding. In addition, ERW straight seam welded pipes are mainly divided into two forms: ERW AC welded steel pipes and ERW DC welded steel pipes.

The straight seam high-frequency welded steel pipe has advanced forming technology, reliable quality, good welding position, stable welding parameters, fast welding speed, high output, and the equipment and technology of the entire production line are currently at the international first-class.

Features:

(1) During the forming process of high-frequency welded steel pipe with straight seam, the springback is small and the residual stress is small.

(2) The deformation hardening effect is small, and the geometric size is accurate after rounding, which is conducive to ensuring the quality of construction and welding.

(3) The shape of the bead of the straight seam high frequency welded steel pipe is good, it is not easy to undercut, and the internal and external welding is not correct for medium defects.

(4) Welds of straight seam steel pipes are distributed at one point on the circumference. Therefore, the weld can be placed in a favorable position according to the requirements of use.

It is mainly used for the transportation of onshore, offshore oil and gas, coal slurry, and ore slurry media, as well as pipes for offshore platforms, power stations, chemicals and urban building structures.