Packaging method of oil casing

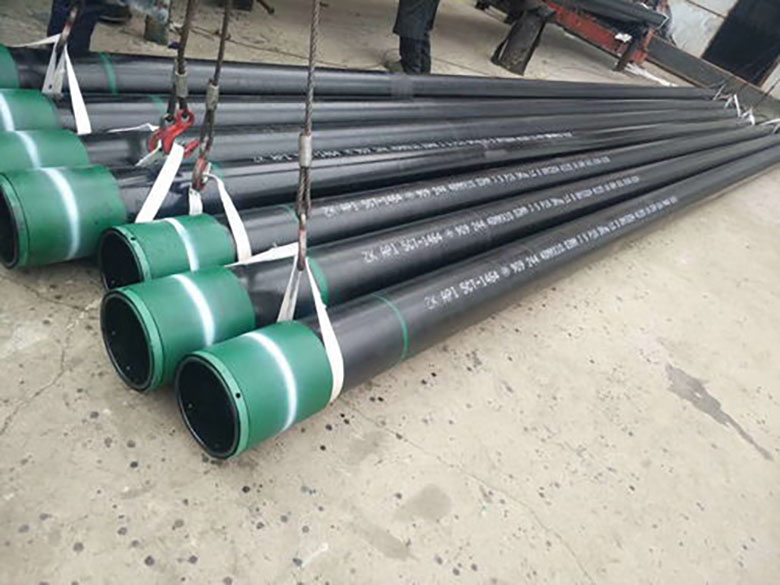

First of all, after the oil casing is produced, its surface is usually sprayed with anti-rust paint to provide preliminary anti-corrosion protection. In addition, in accordance with the requirements of API standards, the outer surface of the pipe will also be sprayed with obvious logos. These logos include manufacturer, ISO certificate number, API logo, API certificate number, nominal diameter, nominal weight, steel grade, length, forming method, Hydraulic pressure, furnace number, batch number, pipe number and other information. If customers have special requirements, corresponding markings will also be made. At the same time, the threaded part of the oil casing will be coated with special thread anti-rust grease to provide additional protection.

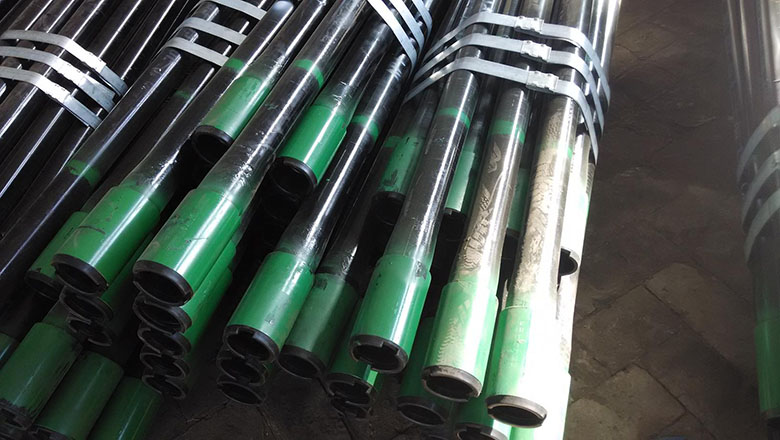

Next, both ends of each oil casing need to be capped with steel and plastic. This step is to protect the wire buckle or chamfer from damage during transportation and storage.

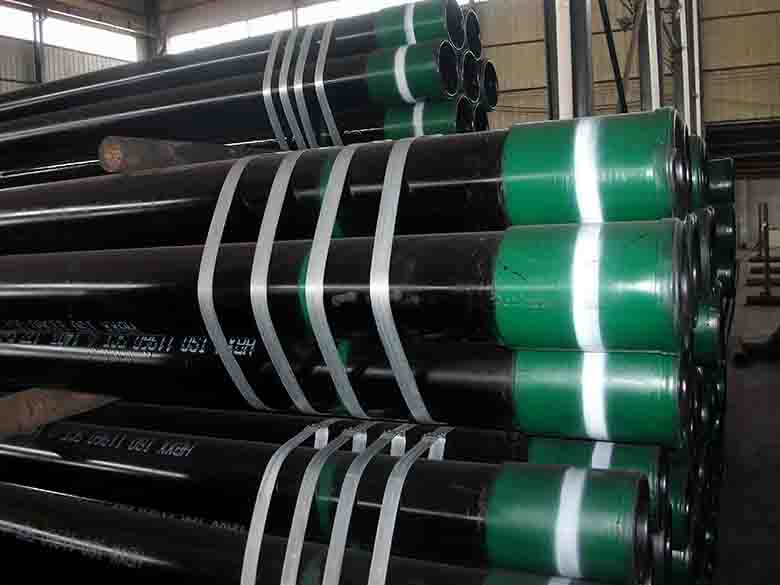

For special oil pipes, steel strips are usually used for packaging. When packaging, it is important to note that the weight of each bundle should not exceed 2.5 tons, which makes it easier to load and unload. At the same time, each bundle of oil casing will be affixed with a waterproof label, which details the manufacturer, product specifications, quantity, remarks and other information for easy identification and tracking.

In general, the packaging method of oil casing is a process that requires both technology and care. Its purpose is to ensure the safety and integrity of oil casing during transportation and storage.