Differences between PSL1 and PSL2 pipelines

The main differences between PSL1 and PSL2 pipelines are reflected in the following aspects:

1. Product specification level and quality level: PSL is the abbreviation of product specification level, and the product specification level of pipeline pipe is divided into PSL1 and PSL2, which can also be understood as the quality level is divided into these two levels. Among them, the specification level of PSL2 is higher than that of PSL1.

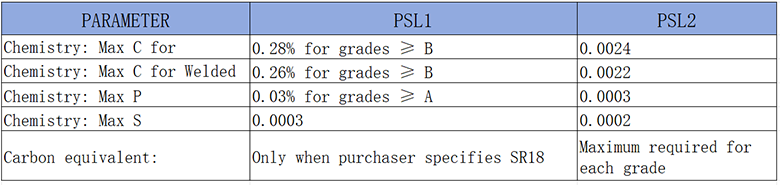

2. Chemical composition and mechanical properties: These two specification levels have different requirements in terms of chemical composition and mechanical properties. PSL2 is more stringent on these indicators to ensure that pipelines can maintain more stable performance in complex and harsh environments.

3. Impact performance and non-destructive testing: All steel grades of PSL2 pipes except x80 need to meet specific impact performance requirements. At the same time, PSL2 pipelines also need to undergo non-destructive inspection one by one, while PSL1 does not require it.

4. Pipe end treatment: Another significant difference is the pipe end treatment. The pipe ends of PSL2 must be sandblasted, while this step is not required for PSL1.