Why does oil casing pipe need rust removal and painting?

Oil casings play a vital role in the oil extraction and production process. They are used in the construction of oil wells to support the well walls, prevent well wall collapse and allow the deployment of drilling and oil production equipment. In order to ensure that the oil casing can work effectively for a long time, the two steps of rust removal and painting are essential.

First of all, rust removal is a key step in oil casing pretreatment. Rust may develop on the surface of oil casing during manufacturing, transportation and storage. These rust stains not only affect the aesthetics of the casing, but more importantly, they will destroy the anti-corrosion layer of the casing, making the casing more susceptible to corrosion. Corrosion can weaken the strength and structural integrity of casing, increasing the risk of well wall collapse and leakage. Therefore, through rust removal, the rust and dirt on the surface can be removed, providing a clean and even surface for subsequent anti-corrosion treatment.

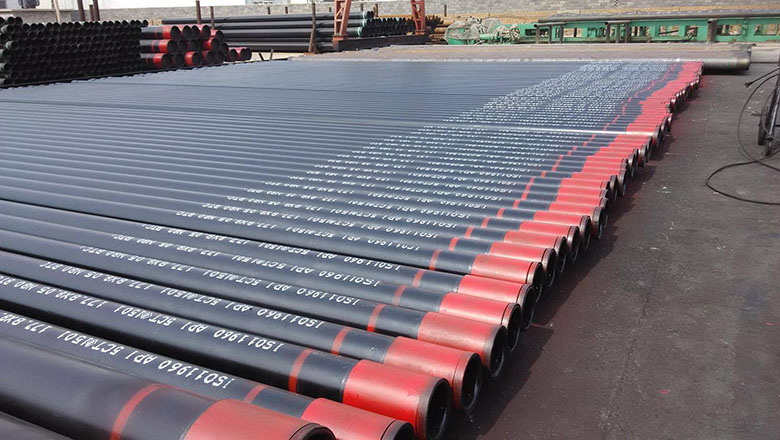

Secondly, spray painting is an important measure for anti-corrosion treatment of oil casing. After rust removal, the surface of the casing needs to be coated with one or more layers of anti-corrosion paint to form a protective film to isolate the casing from contact with moisture, oxygen and other corrosive substances in the external environment. This significantly extends the service life of the casing and reduces repair and replacement costs due to corrosion. In addition, spray painting can also improve the aesthetics of the casing and make it more in line with the overall environmental requirements of the oil extraction site.

To sum up, the main purpose of derusting and painting oil casing is to remove the rust and dirt on the surface and form an anti-corrosion protective film to ensure the long-term, stable and safe use of the casing. These two steps are important for improving the efficiency and safety of oil extraction.