The difference between hard and soft stainless steel materials

Stainless steel is a high-quality alloy steel that resists corrosion. In the application process of stainless steel, the characteristics of its organizational structure often have an important impact on its performance. Different manufacturing processes and chemical compositions can give stainless steel different organizational structures, resulting in hard materials and soft materials.

There are significant differences between the two in many aspects:

1. Composition and characteristics: Hard stainless steel usually contains a higher amount of chromium, such as 18% chromium, to improve its corrosion resistance and hardness. Soft stainless steel usually contains 1~2% carbon to improve its bending elasticity. Hard stainless steel has higher strength, but its corrosion resistance is relatively poor; conversely, soft stainless steel has lower strength, but its corrosion resistance is excellent.

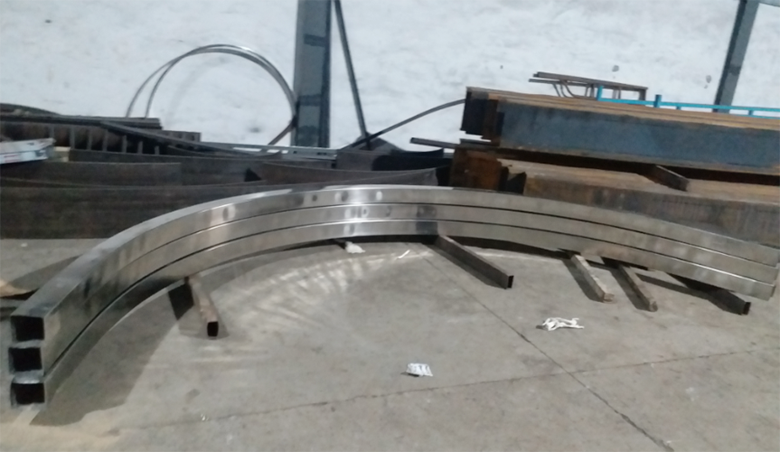

2. Processing performance: Soft stainless steel is easy to process, including cold bending, drawing and cutting operations. The processing performance of hard stainless steel is poor, and annealing and other treatments are often required to obtain better processing results.

3. Application scenarios: Because soft stainless steel has good corrosion resistance and processing properties, it is widely used in the production of various chemical equipment, pressure vessels, and building materials. Due to its high strength properties, hard stainless steel is widely used in places that need to withstand high strength, such as automobile rims and air engine parts.

To sum up, there are significant differences between stainless steel hard materials and soft materials in terms of composition, characteristics, processing performance and application scenarios. When choosing which stainless steel to use, you need to consider the specific application needs and scenarios.