What is the difference between 304, 304H and 304L?

In fact, according to the chromium and nickel content, both are 304 stainless steel. The composition contains 18% Cr and 8% Ni, but the main difference lies in the carbon content.

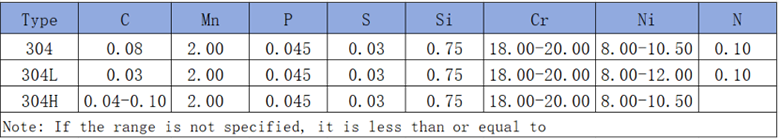

Chemical composition (%) table of 304, 304L and 304H

304 stainless steel, also known as 18-8 stainless steel because it contains approximately 18% chromium and 8% nickel. This material has good corrosion resistance and mechanical properties, making it suitable for a wide range of applications such as construction, manufacturing and food processing.

304L stainless steel is a low-carbon version of 304, with a lower carbon content, usually less than 0.03%. This low-carbon property makes it particularly suitable for applications in corrosive environments, such as the chemical industry and marine engineering.

304H stainless steel is a high-carbon version of 304, with a carbon content usually between 0.04% and 0.1%. This high carbon content enhances its heat resistance in high-temperature environments, making it suitable for high-temperature equipment manufacturing, such as petroleum refining and stove manufacturing.

Mechanical properties table of 304, 304L, 304H

To sum up, the main differences between 304, 304H and 304L stainless steel lie in their chemical composition, characteristics and application scenarios. When choosing which stainless steel to use, comprehensive considerations need to be made based on specific project needs and environmental conditions.