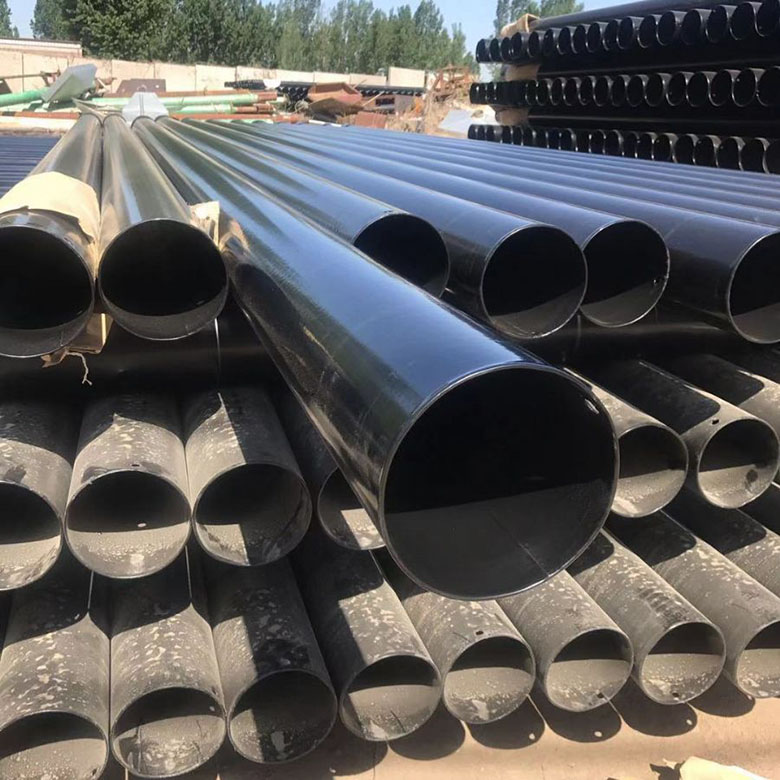

Grades Of Black Steel Pipes

Black steel pipe is commonly used in a variety of industrial applications, including pipelines, construction and infrastructure projects. When comparing Grade A and Grade B black steel pipe, it is important to consider their differences in chemical composition, mechanical properties and specific applications. Understanding the differences between these grades can help ensure the appropriate material is selected for a given project, taking into account factors such as load requirements, environmental conditions and industry standards.

Chemical composition of black steel pipe:

Grade A and Grade B black steel pipes differ due to different chemical compositions, which affects their mechanical properties and suitability for specific applications.

Grade A: Grade A black steel pipe typically has a maximum carbon content of 0.25% and a manganese content ranging from 0.95% to 1.44%. These pipes are designed for general structural and mechanical applications and are typically specified for low pressure fluid transfer and non-critical industrial uses.

Grade B: Grade B black steel pipes have a higher carbon content than Grade A pipes, with a maximum carbon content of 0.30%. The manganese content of Grade B pipe ranges from 0.29% to 1.06%. These pipes are suitable for more demanding applications including high-pressure fluid transfer, structural components and mechanical systems that require increased strength and durability.