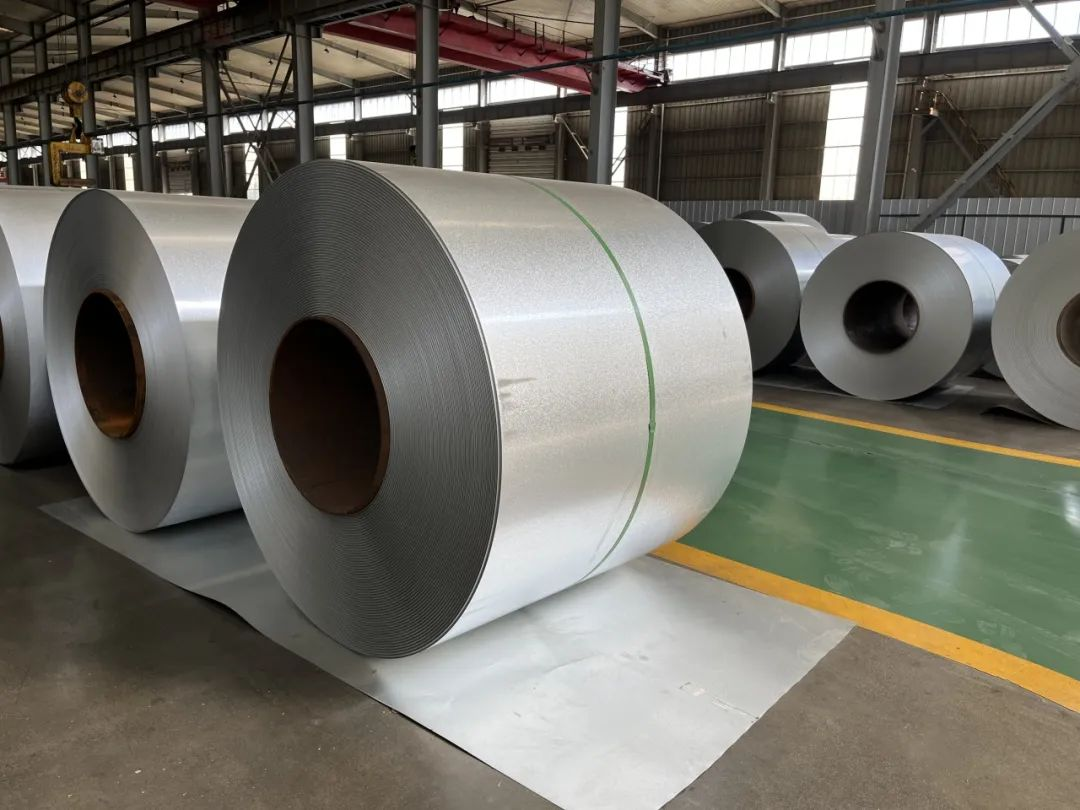

Galvalume coil production process

Galvalume coil is a coil product that has been hot dipped with aluminum-zinc alloy layer. This process is often called Hot-dip Aluzinc. This treatment covers the surface of the steel coil with an aluminum-zinc alloy coating, which improves the corrosion resistance of the steel.

Manufacturing process

1. Surface treatment: First, surface treatment is performed on the steel coil, including oil removal, rust removal, surface cleaning and other processes to ensure that the surface is clean and smooth, and to increase adhesion to the coating.

2. Pretreatment: The surface-treated steel coils are sent into the pretreatment tank and usually undergo pickling, phosphating and other treatments to form a zinc-iron alloy protective layer.

3. Coating preparation: Aluminum-zinc alloy coating is usually a solution composed of aluminum, zinc and other alloying elements, prepared through specific formulas and processes.

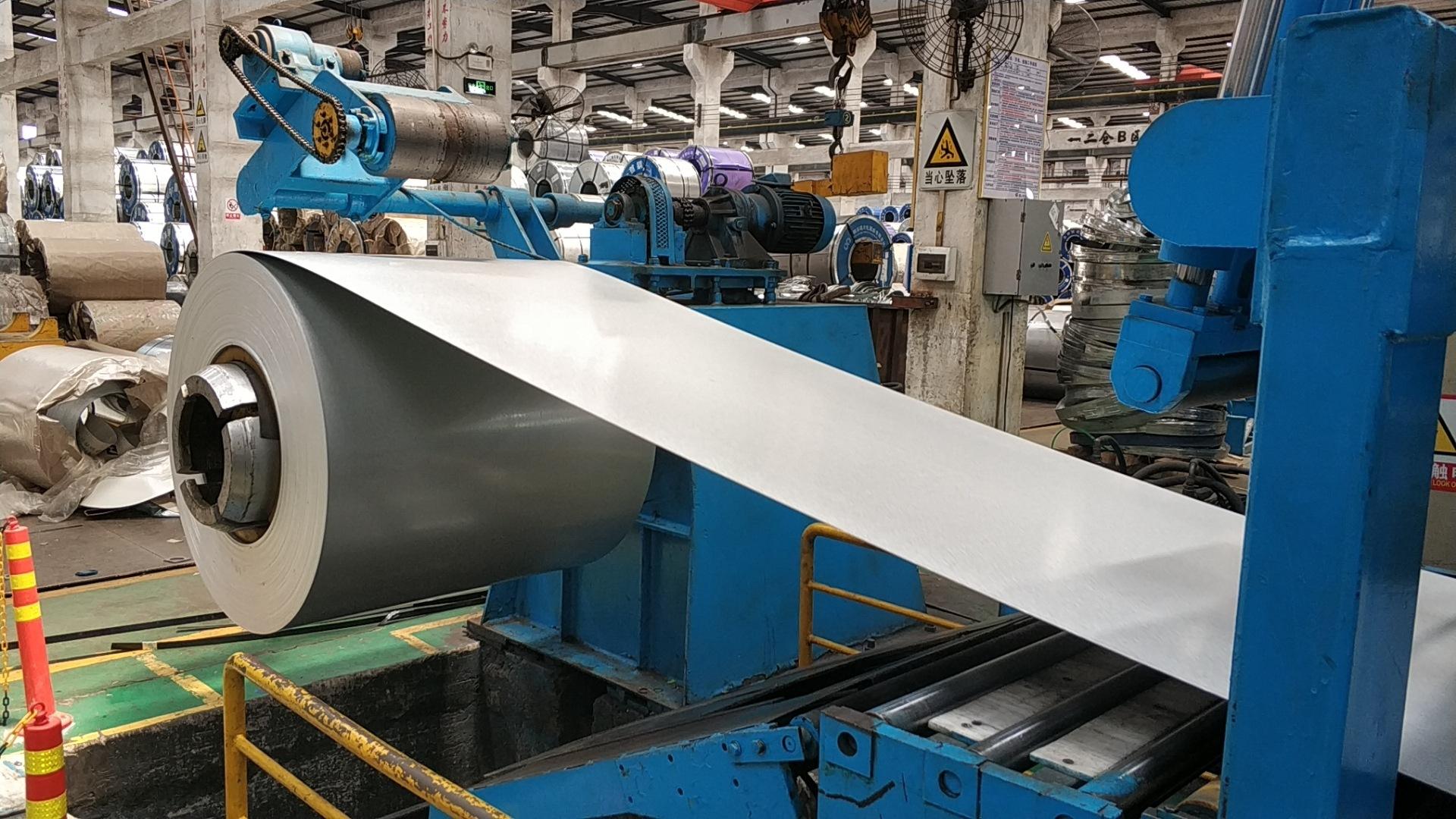

4. Hot dip plating: Pass the pretreated steel coil through a hot dip tank and immerse it in an aluminum-zinc alloy solution at a certain temperature, causing a chemical reaction between the surface of the steel coil and the aluminum-zinc solution to form a uniform layer of aluminum-zinc alloy coating layer. Usually, during the hot dip plating process, the temperature of the steel coil is controlled within a certain range to ensure the uniformity and stability of the coating.

5. Cooling and solidification: The hot-dip plated steel coil is cooled to solidify the coating to form a complete aluminum-zinc alloy protective layer.

6. Post-processing: After completing hot-dip plating, coating surface treatment is usually required, such as coating with anti-corrosion agents, cleaning, drying, etc., to improve the corrosion resistance of the coating.

7. Inspection and packaging: Conduct quality inspection on galvanized steel coils, including appearance inspection, coating thickness measurement, adhesion test, etc. After passing the quality inspection, they will be packaged to protect the coating from external damage.