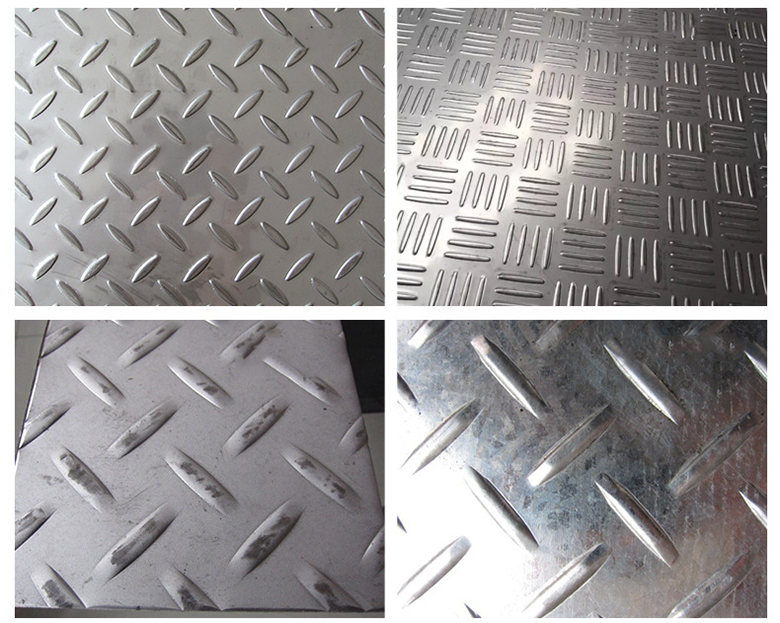

Patterned steel plate

Patterned steel plate is a decorative steel plate obtained by patterning the surface of the steel plate. This treatment can be accomplished by embossing, etching, laser cutting and other methods to create a surface effect with a unique pattern or texture.

The pattern can be a single rhombus, lentil or round bean shape, or two or more patterns can be appropriately combined into a combined pattern plate.

Patterned steel plate manufacturing process

1. Select base material: The base material of Patterned steel plate can be cold-rolled or hot-rolled ordinary carbon structural steel, stainless steel, aluminum alloy, etc.

2. Design patterns: Designers design various patterns, textures or patterns according to needs.

3. Pattern processing:

Embossing: Use special embossing equipment to press the designed pattern onto the surface of the steel plate.

Etching: Using chemical etching or mechanical etching to remove surface material in specific areas to form patterns.

Laser cutting: Laser technology is used to precisely cut the surface of the steel plate to form patterns.

4. Coating treatment: The surface of the steel plate may be treated with anti-corrosion coating, anti-rust coating, etc. to increase its corrosion resistance.

Advantages of patterned steel plates

Patterned steel plate is a high-quality building material. Its surface pattern is not only beautiful and elegant, but can also effectively increase friction and improve anti-skid performance. At the same time, patterned steel plates have excellent strength and toughness and can withstand greater pressure and impact. In addition, it has good corrosion resistance and wear resistance, allowing it to remain beautiful and durable for a long time.

Editor: Lucas

Mail: lucas@yangtzesteel.com