The difference between hot rolling and cold rolling of stainless steel

Steel is an important raw material in industrial production and is needed in many heavy processing industries. Steel plants produce steel according to different production purposes, usually divided into hot rolling and cold rolling.

Differences in production processes

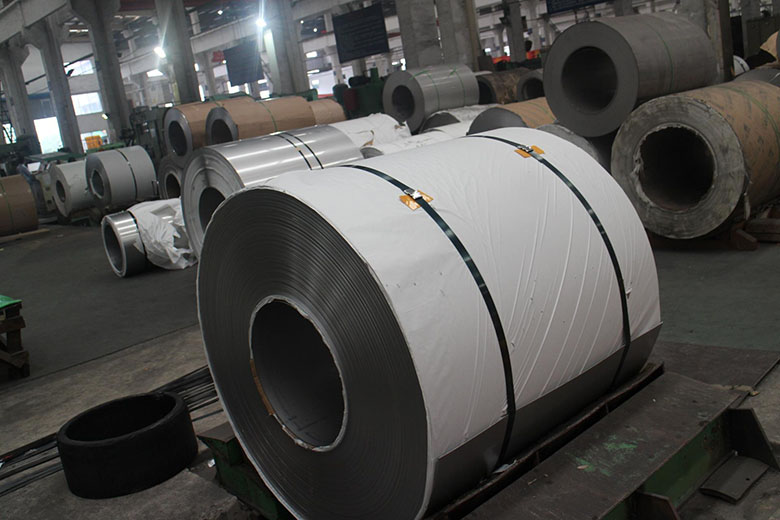

Hot rolling: The plate is cut into raw materials, heated at high temperature, and pressed by the rough rolling unit and the finishing rolling unit.

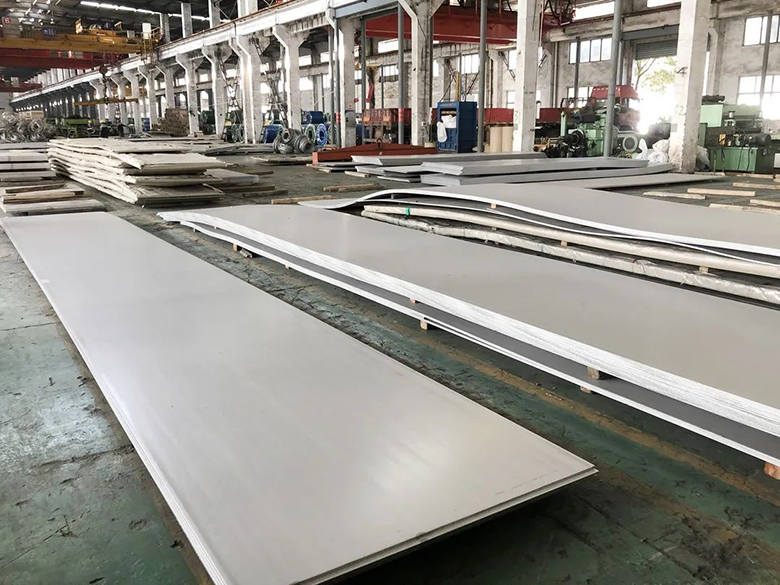

Cold rolling: On the basis of hot rolled coils, it is pickled to remove scale and rolled at room temperature.

Differences in physical properties

Hot rolling: thickness 3.0mm or more, width 1500mm

Cold rolling: thickness less than 3.0mm, width 1000-1240mm

Differences in surface color

Hot-rolled: The surface of hot-rolled plates is darker, mostly brown, and oxide scale is produced due to high-temperature processing. This surface is also called the NO.1 surface.

Cold rolling: The surface of cold-rolled plates is silver-white, and there is no oxide scale when processed at room temperature. This surface is also called 2B surface.

Use

Hot rolling: generally used in machinery and industry; often used in bridges, steel structures, engineering machinery, containers, etc.

Cold rolling: generally used for decorative panels, automobile manufacturing, electrical products, and aviation precision instruments.

Editor: Lucas

Mail: lucas@yangtzesteel.com