Stainless steel pipe manufacturing process

1.Order steel strip

When making pipes, the raw materials for steel strips need to be prepared in advance.

Special pipes require special steel coils and are more expensive than ordinary pipes.

2.Calendering

Use a calender to roll the steel coils and plates like noodles, and roll the coils to the required thickness.

If it is too thin or too thick, the process will be more complicated and the price will increase.

3. Annealing

Since the physical properties of the rolled plate cannot meet the standards and the toughness is not enough after rolling, it needs to be annealed to restore the properties of stainless steel.

Annealing: A metal heat treatment process in which the metal is heated to a certain temperature (900-100 degrees), maintained for a sufficient time, and then cooled at an appropriate speed (usually slow cooling, sometimes controlled cooling).

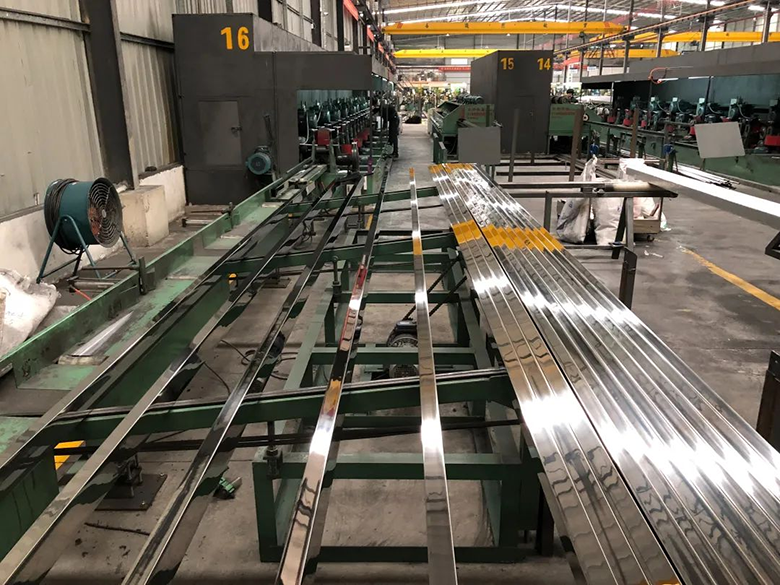

4. Divide into strips

According to the required outer diameter of the pipe, cut the annealed coils and plates as required.

5. Pipe making

The segmented steel strips are put into pipe making machines with molds of different diameters for production, rolled into corresponding shapes, and then welded.

Pipes are generally divided into cold rolling and hot rolling. There are some differences in the production process of different pipes.

6. Polishing

After the pipe is formed, it is surface polished by a polishing machine.

Polishing: refers to a processing method that uses mechanical, chemical or electrochemical effects to reduce the surface roughness of the workpiece to obtain a bright and smooth surface.

Editor: Lucas

Mail: lucas@yangtzesteel.com