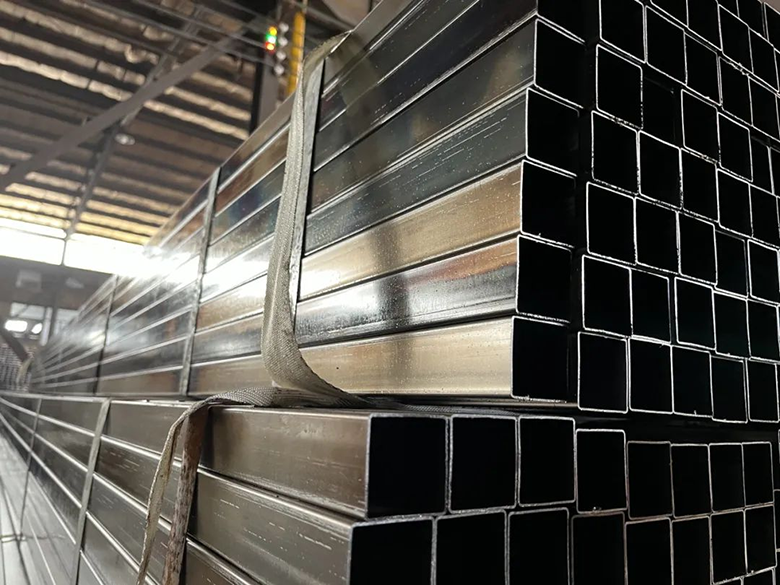

Oiling steel pipes

Steel pipe oiling is a common surface treatment method for steel pipes. Its main purpose is to provide corrosion protection, improve appearance and extend the service life of steel pipes. This process involves applying grease, anti-corrosion film or other coatings to the surface of the steel pipe to reduce exposure to oxygen and moisture, thereby mitigating the risk of corrosion.

Oiling type

1. Rust Inhibitor Oil: Rust inhibitor oil is usually used to provide basic corrosion protection to reduce rust and corrosion on the surface of steel pipes.

2. Cutting Oil: Cutting lubricating oil is mainly used in the processing and cutting process of steel pipes to reduce friction, improve cutting efficiency, and cool tools and workpieces during the cutting process.

3. Hot-Dip Galvanizing Oil: In the hot-dip galvanizing process, the surface of the hot-dip galvanized steel pipe usually requires the application of special grease or lubricating oil to protect the hot-dip galvanized coating and provide additional anti-corrosion.

4. Aesthetic Coating: Steel pipes can also be coated with cosmetic coatings to improve appearance, provide color and enhance decoration.

Oiling method

1. Immersion method: Steel pipes can be evenly coated with lubricating oil or anti-rust oil on their surface by immersing them in an oil coating bath.

2. Brushing method: Oil can also be applied to the surface of the steel pipe manually or automatically using a brush or roller coater.

3. Spraying method: Spraying equipment can be used to spray oil lubricant or lubricating oil evenly on the surface of the steel pipe.

The function of oiling

1. Corrosion protection: Oiling provides effective corrosion protection and extends the service life of steel pipes.

2. Appearance improvement: Oiling can provide a better appearance and improve the texture and beauty of the steel pipe.

3. Reduce friction: Lubricant coating can reduce friction on the surface of steel pipes, which is very useful for some special purposes.

Oiling is a common surface treatment method, and the lubricant type and oiling method can be selected based on the needs of the specific application. In the industrial and construction fields, it helps protect and maintain steel pipes, ensuring their long-term stable operation under various environmental conditions.

Editor: Lucas

Mail: lucas@yangtzesteel.com