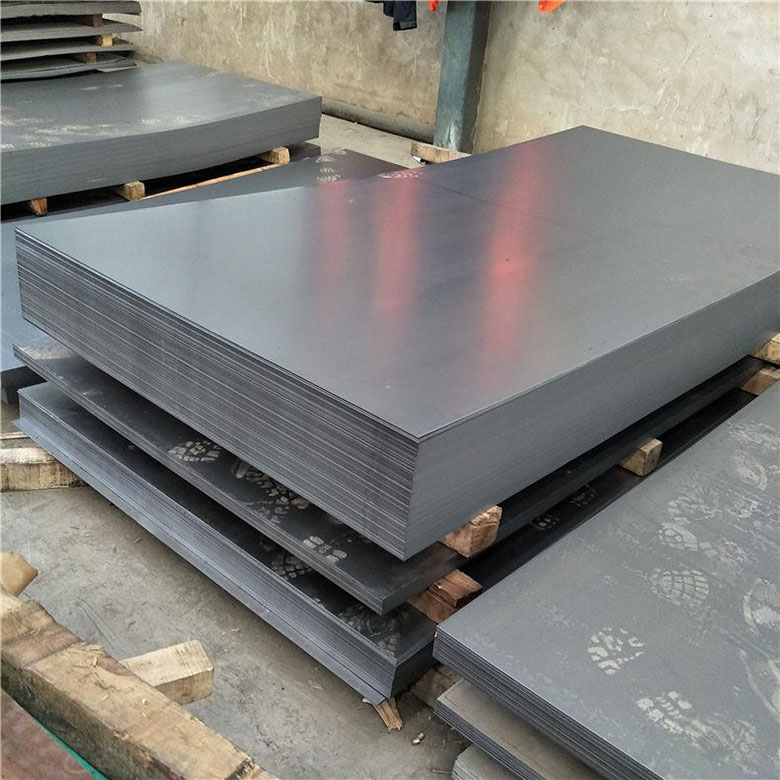

Today’s steel knowledge-cold rolled plate

Cold-rolled plates are made from hot-rolled coils as raw materials and are rolled at room temperature and below the recrystallization temperature, including plates and coils. Among them, those delivered in sheets are called steel plates, also called box plates or flat plates; those that are very long and delivered in rolls are called steel strips, also called coiled plates.

Advantages of cold rolled plate

1. Due to less thermal deformation during cold rolling, its dimensional accuracy is higher and it is more suitable for use in fields that require high-precision dimensions, such as automobile manufacturing and machinery manufacturing.

2. Ultra-thin strips that cannot be produced by hot rolling can be obtained, and the thickness can be less than 0.001mm.

3. The cold rolling process makes the surface quality better, with high flatness and no obvious surface defects. This makes cold rolled plates useful in areas where high surface quality is required.

4. Cold-rolled coils have good mechanical properties and process properties, such as higher strength, lower yield limit and excellent deep drawing performance.

However, it also has some disadvantages, such as poor elasticity and ductility, smaller load capacity, etc.

Cold rolled plate production process

It mainly includes the following steps: First, the raw material is heated and rolled to deform it and reach the required thickness. Then pickling is used to remove the oxide scale and dirt on the surface to improve the flatness and smoothness of the surface. The final oiling treatment prevents surface oxidation and rust, and can reduce friction and scratches during stacking, transportation and processing. The entire process requires strict quality control to ensure product stability and reliability.

Editor: Lucas

Mail: lucas@yangtzesteel.com