Production process of color steel plate

Color steel plate is a composite of steel materials and organic materials. It not only has the mechanical strength and easy forming advantages of steel plates, but also has the good decorative properties and corrosion resistance of coating materials.

The main production processes of the color coating unit include:

Pretreatment process, coating process, baking process.

1. Pretreatment process

It mainly involves cleaning the substrate to remove impurities and oils attached to the surface; and then undergoes composite oxidation and passivation treatment to form a pretreatment film. Pretreatment film is an effective means to improve the bonding force between substrate and coating.

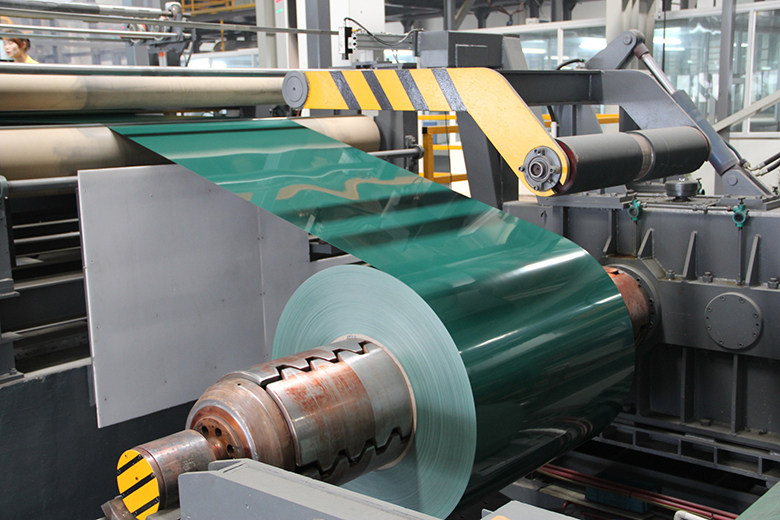

2. Coating process

At present, the most commonly used coating process in color coating units of major steel plants is roller coating. Roller coating brings the paint in the paint tray to the coating roller through the belt roller, and a wet film of a certain thickness is first formed on the coating roller. , and then transfer this wet film to the coating method of the substrate surface.

By adjusting the roller gap, pressure and roller speed, the coating thickness can be increased or decreased within a certain range;

It can be coated on one side or both sides at the same time. This method is fast and has high production efficiency.

3. Baking process

The baking process mainly deals with the curing of the steel plate surface coating, which means that the coating undergoes chemical polycondensation, addition polymerization, cross-linking and other reactions under certain temperatures and other conditions through the main film-forming substances, auxiliary film-forming substances and curing agents. The process of changing from liquid to solid state.

The coating curing baking process generally includes primary coating baking, fine coating baking and their corresponding exhaust gas incineration system.

Subsequent processing of color-coated steel plates

Including embossing, printing, laminating and other processing methods, you can also wax or add a protective film, which not only increases the anti-corrosion effect of the color-coated board, but also protects the color-coated board from scratches during handling or processing.

Editor: Lucas

Mail: lucas@yangtzesteel.com