The difference between I-beam and H-beam

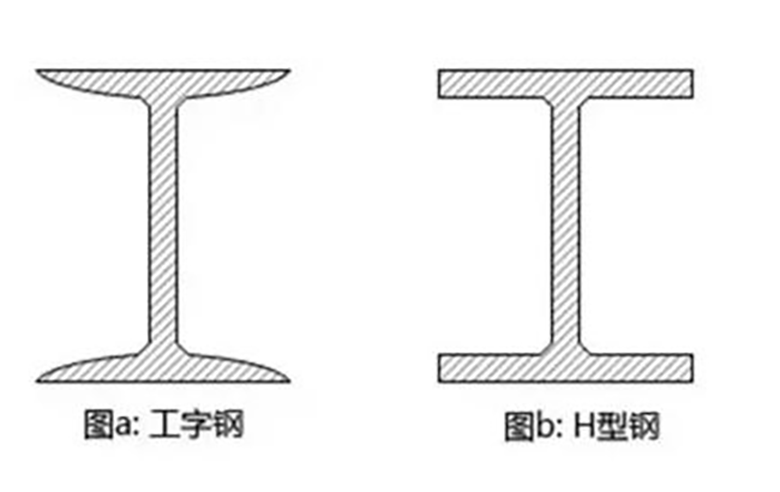

H-beam and I-beam are different in shape, as shown in the figure:

1.I-beam

It is mainly divided into ordinary I-beam, light I-beam and wide-flange I-beam. According to the height ratio of flange to web, it is divided into wide, medium and narrow wide flange I-beams. The first two are produced in sizes 10-60, which means the corresponding height is 10-60cm.

As the name suggests, the I-beam is an "I"-shaped cross-section steel. The inner surfaces of the upper and lower flanges have an inclination, usually 1:6, which makes the flanges thin on the outside and thick on the inside. This causes the I-beam to be in two places. The cross-sectional properties of the main planes vary greatly, making it difficult to utilize the strength properties of steel in applications.

H-shaped steel is an economical cross-section and high-efficiency profile with more optimized cross-sectional area distribution and more reasonable strength-to-weight ratio. It is named because its cross-section is the same as the English letter "H". Since all parts of H-shaped steel are arranged at right angles, H-shaped steel has the advantages of strong bending resistance in all directions, simple construction, cost saving and light structural weight, and has been widely used.

3. The difference between the two

Regardless of whether I-beam is ordinary or light, since the cross-section size is relatively high and narrow, the moment of inertia of the two main axes of the cross-section is quite different, so it is generally only used directly for bending in the plane of its web. components or form them into lattice-type stressed components. It is not suitable to use axial compression controls or components that are curved in the vertical and web planes, which greatly limits its application range.

H-shaped steel is an efficient and economical profile (others include cold-formed thin-walled steel, profiled steel pipes, etc.). Due to their reasonable cross-sectional shape, they can make the steel more efficient and improve its load-bearing capacity. Different from the ordinary I-shaped steel flange, the flange of the H-shaped steel is widened, and the inner and outer surfaces are parallel throughout the length. This makes it easy to connect with other components with high-strength bolts. Its size is reasonable and the models are complete, which is convenient. Design selection.

Editor: Lucas

Mail: lucas@yangtzesteel.com