What are the processing techniques for angle steel?

Angle steel is a commonly used building material. Due to its special shape, special processes are required during processing to ensure its quality and accuracy. The following are some common angle steel processing techniques:

1. Shearing processing

Shearing processing refers to cutting the angle steel with a shearing machine or electric shear. You need to pay attention to selecting a suitable knife edge for better processing, and also pay attention to adjusting the cutting angle to ensure that the cutting angle is correct.

2. Welding processing

Welding processing refers to processing angle steel through welding. This method can combine multiple angle steels or connect angle steel with other materials. Surface treatment is required before welding to ensure that the interface surface is smooth, which can effectively improve the welding quality.

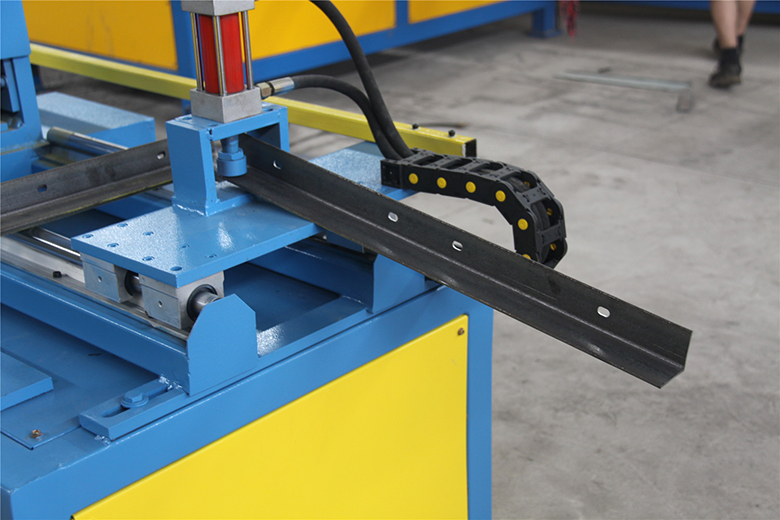

3. Drilling processing

Drilling refers to perforating angle steel to facilitate other processing or connections. Care needs to be taken to ensure that the holes are evenly spaced and sized to ensure hole accuracy.

4. Bending processing

Bending processing refers to bending angle steel through mechanical pressure in order to achieve a certain bending angle and shape. Pay attention to controlling the processing speed and angle accuracy to ensure that the angle and shape after bending meet the requirements.

5. Surface treatment: Surface treatment of angle steel can improve its corrosion resistance and aesthetics. Common surface treatment methods include spraying, sandblasting and galvanizing.