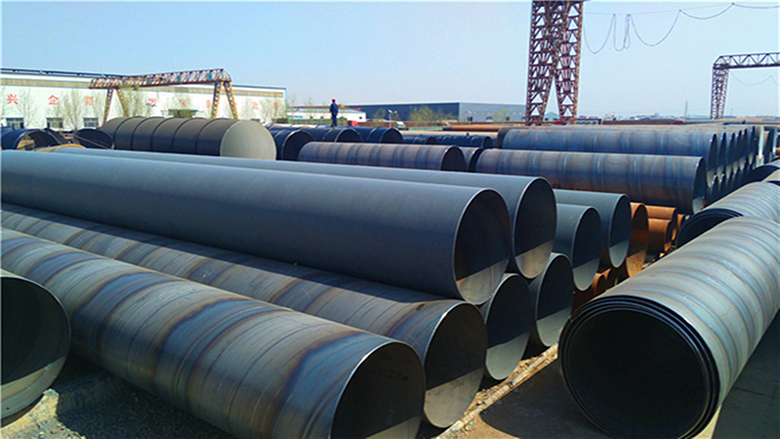

How to avoid wear and tear of spiral steel pipes during transportation

As a large pipe, spiral steel pipes should be careful to avoid collision and friction during transportation and loading and unloading, as the surface of the pipe is usually coated with oil-based paint to ensure corrosion resistance and increase smoothness. Once rubbed, it is easy to damage the paint surface, which will affect subsequent use.

1. During the loading and unloading process, care should be taken and a soft cushion can be laid underneath the transport truck to reduce the impact force.

2. If the buyer has special requirements for the packaging materials and methods of spiral steel pipes, they should be specified in the contract; If not specified, the packaging materials and packaging methods shall be selected by the manufacturer.

3. The packaging materials should comply with relevant regulations. If no packaging materials are required, they should meet the intended use to avoid waste and environmental pollution.

4. If the customer requests that the spiral steel pipe should not have any damage such as bumps on the surface, protective devices can be considered between the spiral steel pipes. Protective devices can use rubber, grass rope, fiber cloth, plastic, pipe caps, etc.

5. Thin walled spiral steel pipes can be protected by internal support or external frame due to their thick and thin walls. The material of the bracket and outer frame is the same as that of the spiral steel pipe.