Surface treatment methods for stainless steel

1. Mirror treatment, which involves polishing the outer layer of stainless steel, can be divided into two methods: physical and chemical, or local polishing can be applied to the surface. It can make stainless steel more concise, high-end, and fashionable.

2. Sandblasting treatment mainly utilizes the force obtained from air compression to apply the sprayed material to the outer layer that needs to be treated at high speed, which can change the shape of the outer layer.

3. Chemical treatment mainly involves the combination of chemistry and electricity to form a stable compound on the outer layer of stainless steel. The most common type of electroplating is chemical treatment.

4. Surface coloring refers to the use of coloring techniques to change the color of stainless steel, making it more diverse and not only adding color, but also improving its wear and corrosion resistance.

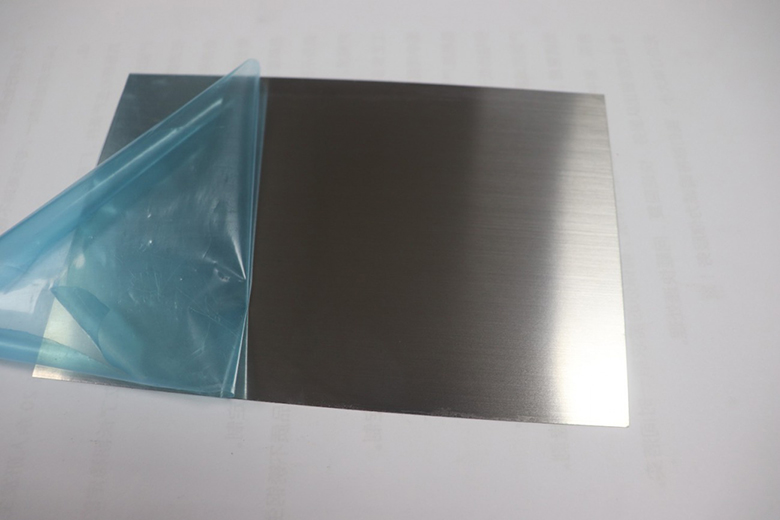

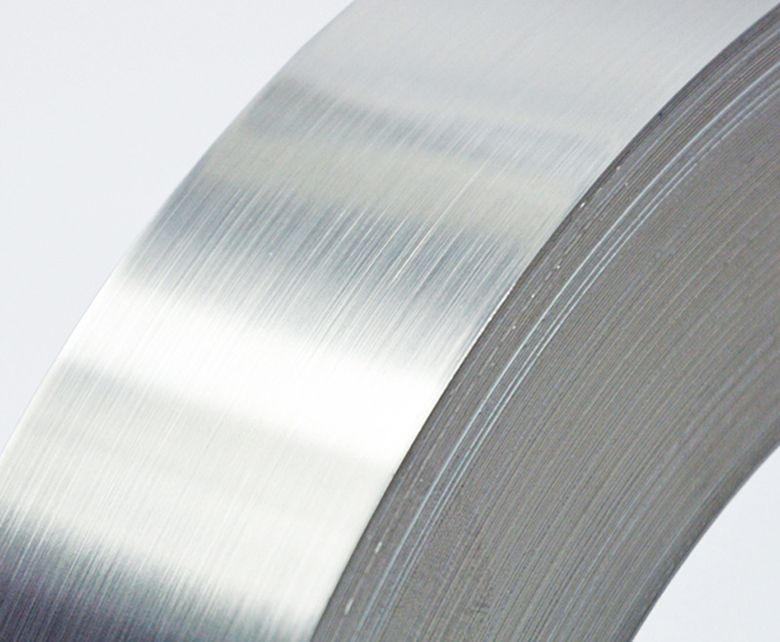

5. Surface wire drawing treatment is a common decorative technique in daily life, which can form many patterns, such as threads, ripples, and spiral patterns. The treated surface is very smooth and delicate, and the wear resistance is also enhanced. It is widely used in electronics, electrical appliances, and mechanical equipment.

6. Spray coating is fundamentally different from the coloring treatment above, as it requires different materials. Spray coating may damage the oxide layer of stainless steel, but it can obtain the most colorful stainless steel products in the simplest way and also change the feel of stainless steel.