What are the differences between stainless steel round pipes and square pipes

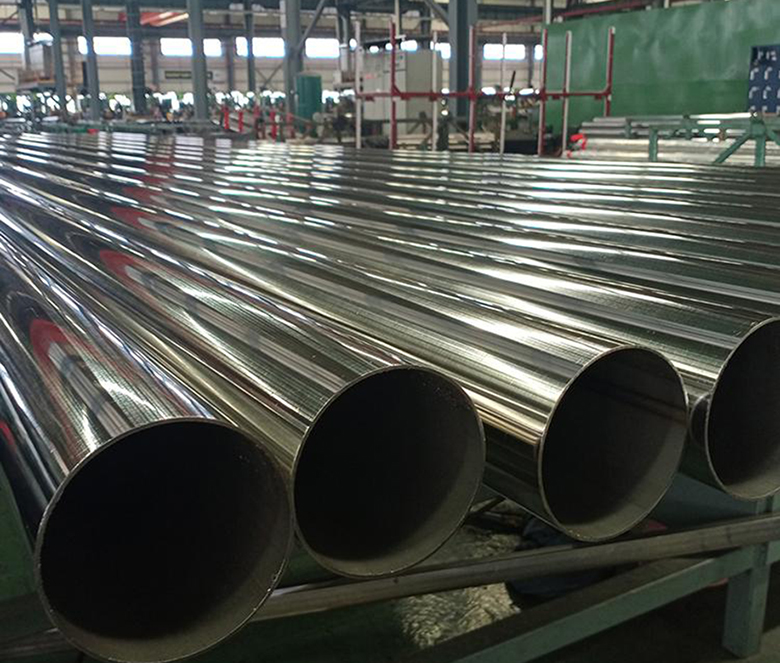

1. Production difference: Round pipes are made of stainless steel strips extruded into a circular shape and then welded (stainless steel welded pipes), or perforated from the entire round steel (stainless steel seamless pipes). The square tube is first made into a circular tube and then extruded into a square tube through a mold. The square tube has an additional process, so the price will also be higher.

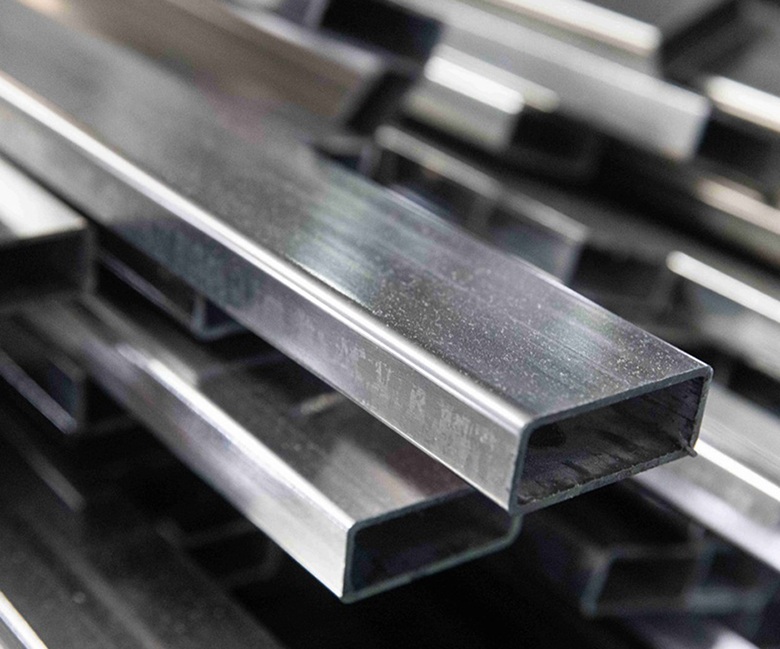

2. Differences in pipe wall processes: Most stainless steel round pipes have polished outer walls, while square pipes have brushed surfaces. This is because the four corners of the square tube are not easy to polish, and the square tube is easier to scratch, so making a brushed surface can reduce the presence of scratches. Some circular pipes have a frosting effect on their surface to prevent slipping, and the particle size can be adjusted.

3. Differences in pipe opening process: The pipe opening of circular pipes can be processed by shrinking, expanding, shrinking, reducing, curling, chamfering, etc., but square pipes cannot be processed.

4. Structural stress difference: The surface of the circular tube is subjected to more uniform force; The stainless steel square tube has four 90 degree angles and is not easy to rotate or twist, making it more secure when fixing certain objects. In home furnishings such as our doors and anti-theft windows, square tubes are generally used as frames, while round tubes are used as linings, which combine to make the items both sturdy and resistant to external impact.