The production process of stainless steel square tubes and how to judge inferior products?

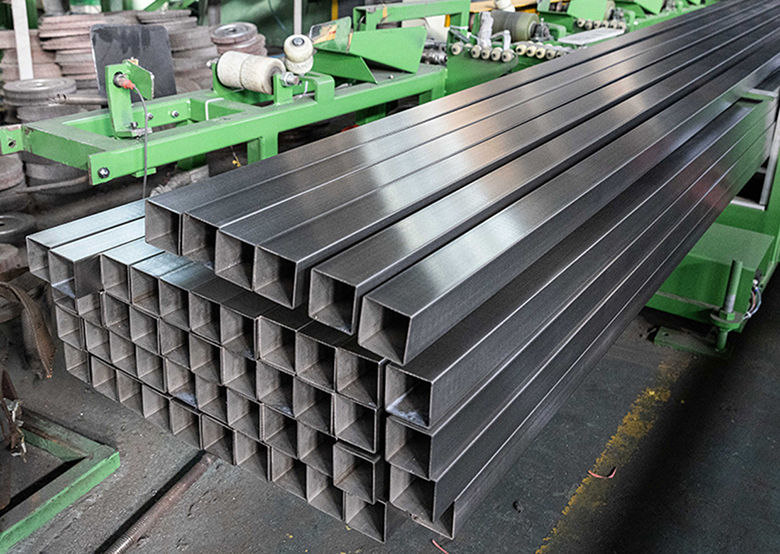

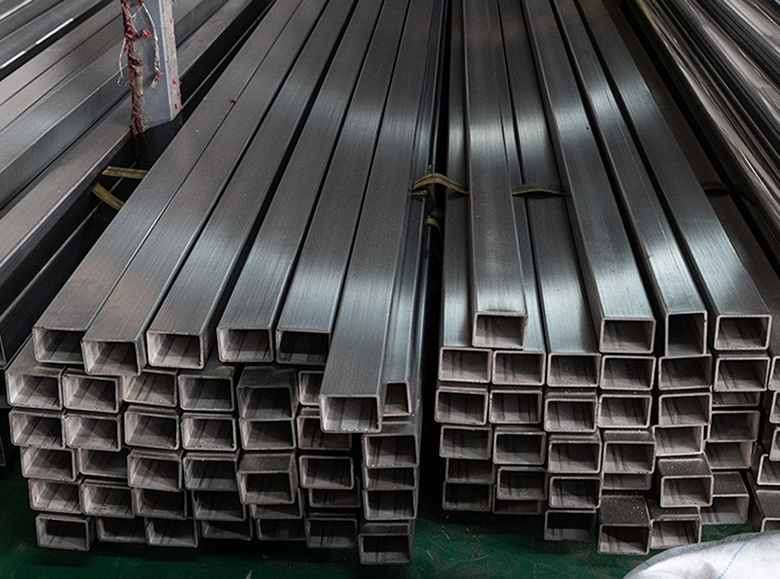

Stainless steel square tubes are made by squeezing stainless steel circular tubes. After heat treatment, stainless steel round pipes with no surface defects, cracks, or bends are placed on the rolling equipment platform and extruded into shape. Subsequently, straightening processing is carried out. Afterwards, the factory's quality inspection personnel will inspect the mechanical properties, chemical analysis, tensile testing, and other processes. After confirming that there are no errors, proceed with the cutting of the saw head. Subsequently, the mechanical polishing process is carried out. The polished stainless steel square tubes will be packed with packaging bags by the packaging personnel, and can be directly shipped or stored in the warehouse.

What type of stainless steel square tube is inferior?

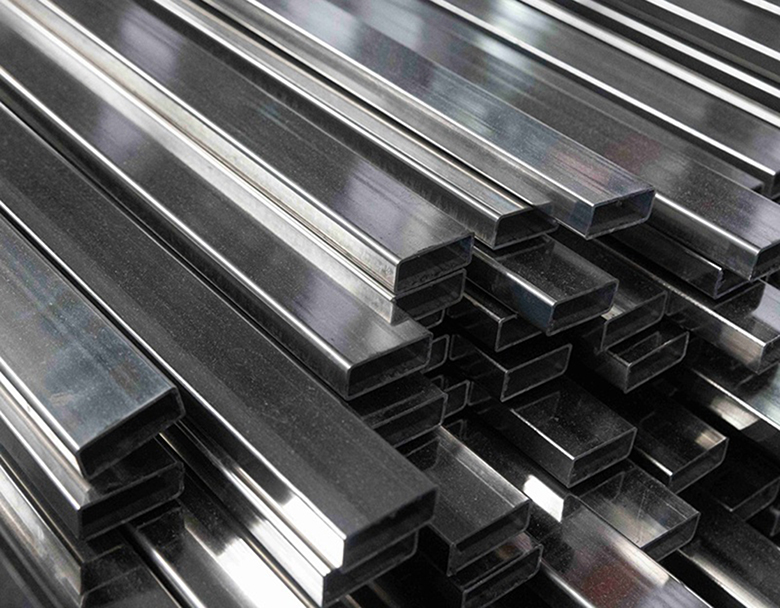

1. The outer surface of inferior stainless steel square tubes is uneven. Due to the excessive pursuit of profit by manufacturers of low-quality stainless steel square tubes, the phenomenon of low surface flatness often occurs.

2. Poor quality stainless steel square tubes are prone to scabbing on the surface.

3. The surface is prone to cracks because its billet is made of adobe, which has many pores. During the cooling process, the adobe undergoes cracks due to thermal stress, which can occur after rolling.

4. Easy to scratch due to poor quality stainless steel square tube manufacturers' simple equipment, which can easily produce burrs and scratch the surface of the steel. Deep scratches reduce the strength of steel.

5. The cross-section of low-quality stainless steel square tubes is irregular because the manufacturer, in order to save materials, has reduced the strength of the stainless steel square tubes significantly by reducing the pressure on the first two rolls of the finished product, which does not meet the standards for the overall dimensions of stainless steel square tubes.