What are the methods for anti-corrosion of steel pipes?

Steel pipe anti-corrosion generally includes coating anti-corrosion and electrochemical anti-corrosion, which are two types of anti-corrosion.

Coating anti-corrosion: It refers to applying paint like materials on the surface of steel pipes, which can isolate various corrosive objects. It is one of the most basic methods for anti-corrosion of steel pipes.

1. Outer wall anti-corrosion coating

External wall anti-corrosion is a anti-corrosion layer coated on the surface of anti-corrosion steel pipes, mainly used to isolate the contact between the steel pipes and the external environment, and prevent the steel pipes from being corroded and oxidized

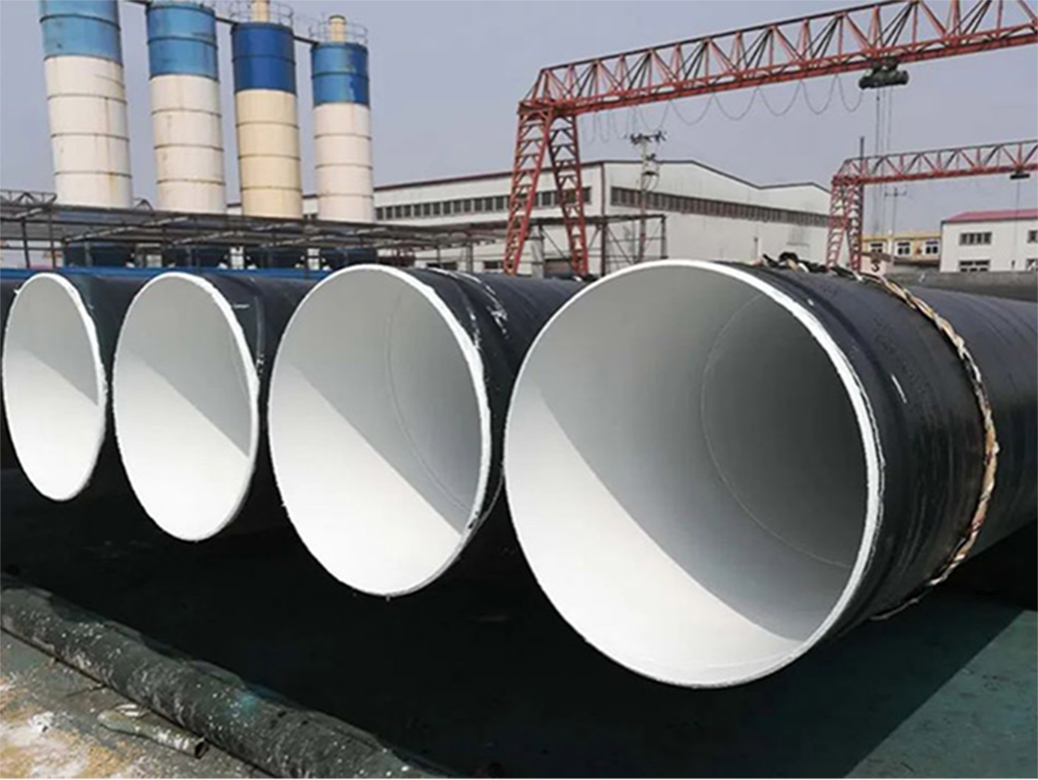

2. Inner wall anti-corrosion coating

A thin film applied to the inner wall of a pipe to prevent corrosion, reduce frictional resistance, and increase throughput. To ensure that the coating adheres firmly to the pipe wall, surface treatment must be carried out on the inner wall of the pipe.

3. Anti corrosion and insulation coating

On medium and small diameter hot oil or fuel oil pipelines, in order to reduce the heat dissipation of the pipeline to the soil, a composite layer of insulation and anti-corrosion is added to the outside of the pipeline. The commonly used thermal insulation material is rigid polyurethane foam. This material has a soft texture. To improve its strength, a layer of high-density polyethylene is added outside the insulation layer to form a composite material structure to prevent groundwater from seeping into the insulation layer.

Electrochemical corrosion protection: It is the protection of the cathode. If there is liquid circulating inside the steel pipe, rust inhibitor or anti-corrosion agent can be added.

Galvanizing of steel pipes refers to immersing the untreated surface of steel pipes into molten zinc solution and firmly bonding the surface of steel pipes with the zinc layer through chemical reactions. After galvanizing the steel pipe, a current system is formed between the anode (zinc layer) and the cathode (steel pipe). The zinc coating serves as the anode and undergoes electrochemical reactions in a corrosive environment, causing fine currents to be generated on the surface of the steel pipe. This current system can form a protective layer that plays a role in anti-corrosion of steel pipes.