Introduction to Types of Color Coated Roll Coatings

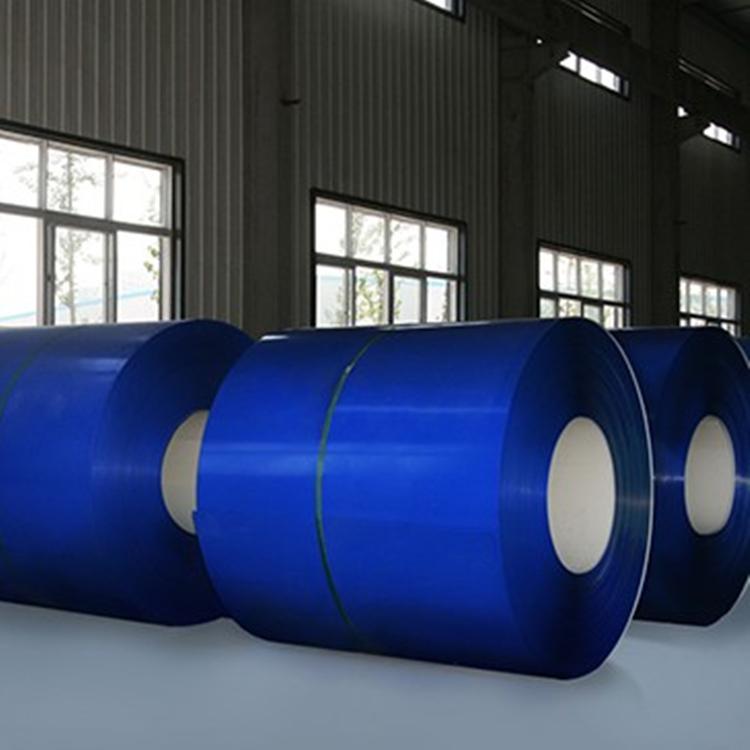

PPGI(Prepainted galvanized steel coils) has a wide variety of coatings, and different coatings have different characteristics and application fields. Common PPGI coatings include organic coatings, inorganic coatings, composite coatings, etc.

(1) Organic coating

Organic coating is the most common coating type in PPGI, which has good aesthetics and ease of processing. Organic coatings can resist atmospheric corrosion and water erosion, extending the service life of PPGI. According to different usage scenarios, organic coatings can be divided into polyester coatings, acrylic coatings, polyurethane coatings, etc. These coatings have different colors, glossiness, and corrosion resistance, and can be customized according to customer needs.

(2) Inorganic coating

Inorganic coating is a coating mainly composed of inorganic materials, which has excellent corrosion resistance and oxidation resistance. Inorganic coatings can resist various chemical corrosion and high-temperature oxidation, and are suitable for occasions with high requirements for corrosion resistance, such as chemical engineering, marine engineering, and other fields. Common inorganic coatings include zinc based chromate coatings, silicate coatings, phosphate coatings, etc.

(3) Composite coating

Composite coating is a coating composed of organic and inorganic coatings, which combines the advantages of organic and inorganic coatings and has better corrosion resistance and aesthetics. Composite coatings can resist various corrosion factors such as atmospheric corrosion, water erosion, and chemical corrosion, and are suitable for occasions with high requirements for corrosion resistance. Common composite coatings include silicone modified polyester coatings, polyester/zinc based chromate composite coatings, etc.

In addition to the three common PPGI coatings mentioned above, there are also some special coatings, such as nanomaterial coatings, ceramic coatings, etc. These special coatings have better performance and characteristics, which can meet stricter usage requirements.

The coating of PPGI has significant characteristics such as high aesthetics, excellent corrosion resistance and processing performance, and good adhesion. The coating has rich colors and high glossiness, which can meet the aesthetic needs of different customers. At the same time, the coating can effectively resist various factors such as atmospheric corrosion, water erosion, and chemical corrosion, improving the service life of PPGI. In addition, the coating has good processing performance and can meet various processing accuracy and appearance requirements. Most importantly, there is a strong adhesion between the coating and the substrate, which can ensure the stability and durability of PPGI during use.