Grinding/Drawing of Stainless Steel Surface Treatment Process

In order to improve the quality and aesthetic appearance of stainless steel surfaces, many customers require sanding treatment on stainless steel surfaces.

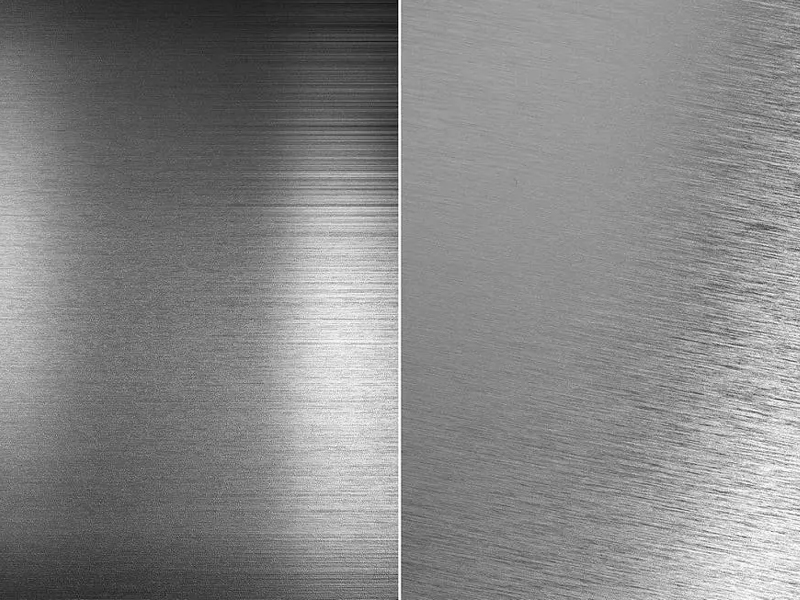

Brushing, also known as wire drawing, forms a filamentous texture effect on the surface of stainless steel after surface treatment. Its surface is matte, and a meticulous observation can reveal that there are threads of texture on the surface of stainless steel, but if touched by hand, the surface will not feel uneven.

Stainless steel that has undergone wire drawing treatment is more wear-resistant than stainless steel that has not undergone surface treatment, appearing more upscale and can extend its service life.

However, the specific process of wire drawing technology is definitely unknown to everyone, so let me introduce it in detail.

There are two different processing methods for sanding, one is through manual sanding. This processing method requires high technical experience and control of workers. If the technology is not in place, the ground silk will become uneven in thickness, which will have a certain impact on the overall aesthetics.

Hand frosted (brushed)

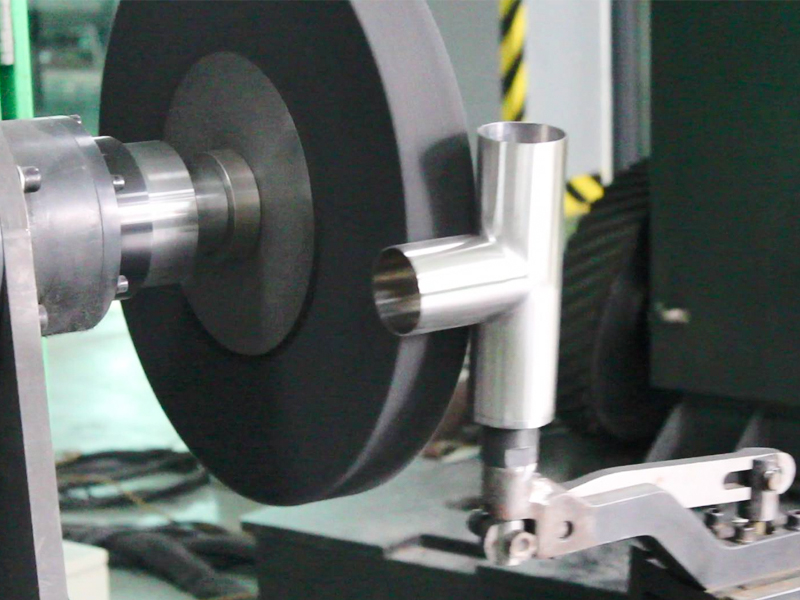

Another method is to use a machine for wire drawing, as the work is fully automated by the machine, so the depth and thickness of the wire drawing can be better controlled, and the speed is relatively faster.

Machine sanding (wire drawing)

So now Yangtze Steel chooses this processing method for processing.

Classification of frosting

Dry sanding: Use sanding tape to directly polish the stainless steel strip without adding any grinding fluid or other lubricants.

Wet sanding: During the grinding process, the grinding fluid must be sprayed. Wet grinding can be divided into water grinding and oil grinding.

Water mill: The grinding fluid is water.

Oil grinding: The grinding fluid is oil, with a finer grain compared to water grinding.

Plate grinding: Cut the stainless steel coil into a certain size flat plate first, and then grind the flat plate individually. Both dry and wet types are available.

Roll grinding: Grinding the entire roll, usually wet grinding.

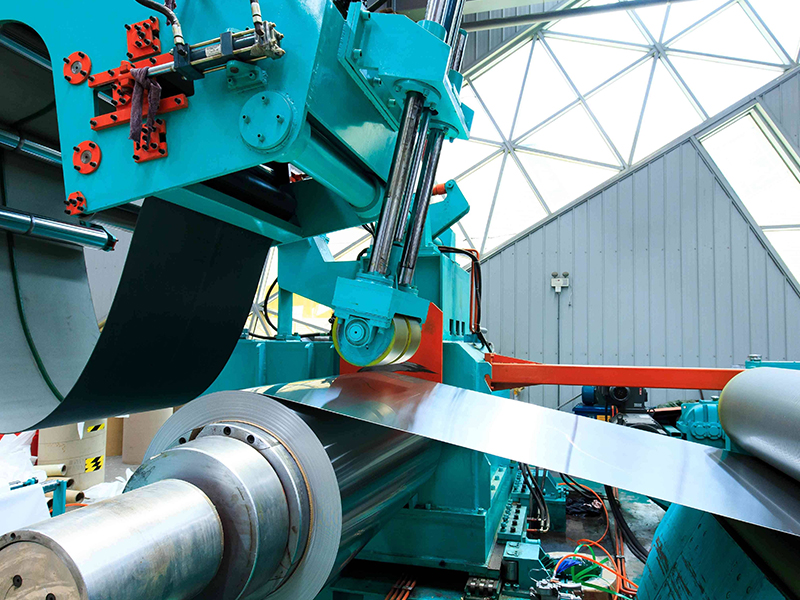

Yangtze Steel Stainless Steel Processing Plant Whole Roll Oil Grinding Production Line

The main processes of frosting (wire drawing) process include unwinding, snowflake sanding machine, wire drawing, cleaning and drying machine, and winding.

Deconvolution

wire drawing

The tension roller and contact roller can be precisely controlled to move up and down through software, providing appropriate tension for the sand belt and providing appropriate downward pressure for the stainless steel belt. The horizontal guide roller provides upward support for the steel strip while avoiding deformation caused by sanding of the stainless steel strip.

If the tension of the sand belt is too small, it can easily slip, which can affect the lifespan of the sand belt. The greater the pressure exerted by the contact roller on the stainless steel strip, the greater the cutting force, and vice versa, which can reduce the grinding effect.

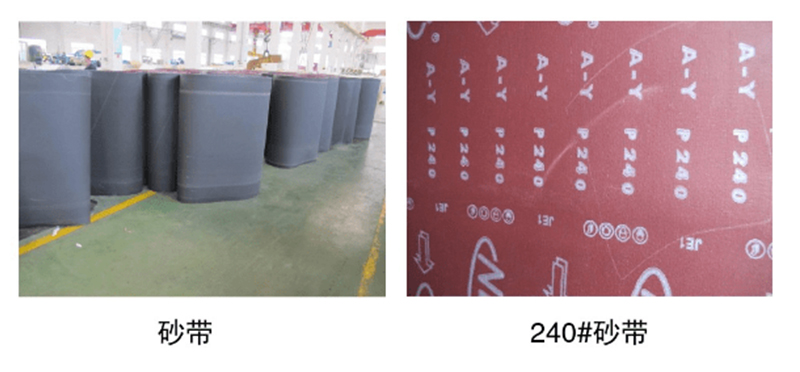

Selection of Belt Number

1. According to the size of the abrasive particle size, the abrasive belt is divided into multiple models.

80 #~220 # are coarse grains, and 240 # and above are fine grains. The sand belts used in actual production include 120 #, 150 #, 180 #, 240 #, 320 #, and 400 #. Among them, 180 #, 240 #, and 320 # are the most widely used.

2. The larger the abrasive number, the smaller the particle size, and the smaller the cutting amount.

Therefore, in sanding machines with several grinding heads, the front grinding head selects a larger number of abrasive belts, which have a large cutting amount and are easy to eliminate burrs, rust, and oil stains on the surface of the steel strip. Later, use a small number of sand belts, which have a small cutting amount but can achieve a finer, more uniform surface effect.

3. The particle size of the abrasive belt increases with the grinding time, and the abrasive is worn and the number increases. For example, after using 80 # abrasive belt for a period of time, the effect is equivalent to 100 # or 120 #. In actual production, the sand belt that has been used for a period of time by the front grinding head is often placed on the back grinding head to continue using.

Principles for selecting abrasive belts for wire drawing

There is no fixed number of sand belts for wire drawing. To achieve a wire drawing effect, first grind the snowflake sand and then wire drawing. This is more beautiful, but the cost is high. However, some customers also require direct wire drawing. In summary, the selection of abrasive belts is mainly based on the needs of customers.

The Role of Grinding Fluid

1. Instant removal of detached abrasives and debris to ensure good grinding results;

2. Reduce temperature to avoid burns and grinding cracks on stainless steel strips.

Explanation: During the sanding process, a large amount of heat is generated, but the thermal conductivity of stainless steel is poor (the thermal conductivity of stainless steel is low, only 1/3 to 1/4 of 45 steel). The grinding fluid can immediately cool the stainless steel strip, avoiding burns and grinding cracks caused by the instantaneous high temperature during grinding.

Therefore, compared to dry grinding, wet grinding has a better grinding effect due to the effect of grinding fluid during grinding.

Cleaning and drying machine

1. The function of the cleaning and drying machine is to remove residual foreign objects such as detached abrasives, grinding debris, and grinding oil from the steel strip, and to perform drying.

2. During the cleaning stage, the stainless steel strip comes into contact with the brush roller, and foreign objects are removed under cold and hot water cleaning. The dryer uses a heating wire for heating and a fan to extract hot air for drying.

Rewind

This is the main process of frosting (wire drawing) technology. Yangtze Steel can produce long wire drawing, short wire drawing, coarse sand drawing, fine sand drawing, cross pattern drawing, random pattern drawing, original color drawing, color drawing, straight drawing, random drawing (and pattern), drawing ripple, drawing thread, and so on.

If you need to do frosting (wire drawing), find Yangtze Steel.