The purpose of angle steel

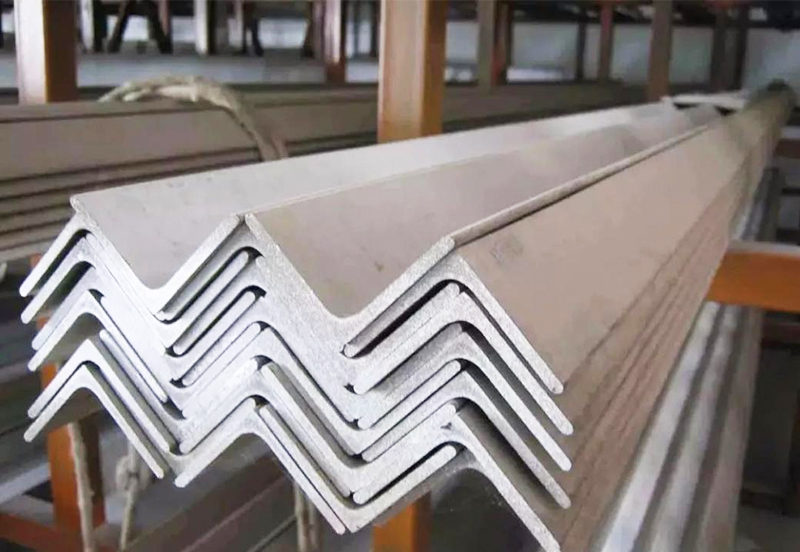

Introduction to angle steel:

Angle iron, commonly known as angle iron, is a long strip of steel with two sides perpendicular to each other and forming an angle shape. There are two types of angles: equal angle steel and unequal angle steel. The two sides of an equilateral angle steel have equal widths. Its specifications are based on edge width × Edge width × The thickness of the edge is expressed in millimeters. As shown in "ě 30 × thirty × three ", which refers to an equilateral angle steel with an edge width of 30 millimeters and an edge thickness of 3 millimeters. It can also be represented by a model, which is the number of centimeters of the edge width, such as {3 #. The model does not represent dimensions of different edge thicknesses in the same model. Therefore, the dimensions of the edge width and edge thickness of the angle steel should be fully filled in the contract and other documents to avoid using a separate model. The specifications of hot-rolled equilateral angle steel are 2 # -20 #. The angle steel can be composed of various load-bearing components according to different structural needs, and it can also be used as a connection between components. The angle steel is widely used in various building and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, and reaction towers.

Mechanical properties:

(1) Inspection method:

①Tensile test method. The commonly used standard inspection methods include GB/T228-87, JISZ2201, JISZ2241, ASTMA370 ГОСТ 1497, BS18, DIN50145, etc.; ②Bending test method. The commonly used standard inspection methods include GB/T232-88, JISZ2204, JISZ2248, ASTME290 ГОСТ 14019, DIN50111, etc.

(2) Performance indicators: The main inspection items for evaluating the performance of angle steel are tensile test and bending test. The indicators include yield point, tensile strength, elongation, and bending qualification.

Weight calculation:

Weight per meter=0.00785 * (edge width+edge width - edge thickness) * edge thickness

For example, 50 * 5 angle steel: (50+50-5) * 5 * 0.00785=3.73 (this algorithm can only roughly calculate the weight of the angle steel)

Process during the use of angle steel:

Angle steel belongs to the carbon structural steel used for construction, which is a simple section steel, mainly used for metal components and factory frames. Angle steel has the characteristics of good weldability, plastic deformation performance and certain mechanical strength in use. Angle steel is mainly used for making frame structures, such as high-voltage transmission towers, frames on both sides of steel bridge main beams, columns and arms of tower cranes on construction sites, columns and beams in workshops, and small places such as flower pot shaped shelves placed on the roadside during festivals, and racks hanging air conditioning and solar energy under windows.

So what processing equipment is used to process angle steel during the use of angle steel?

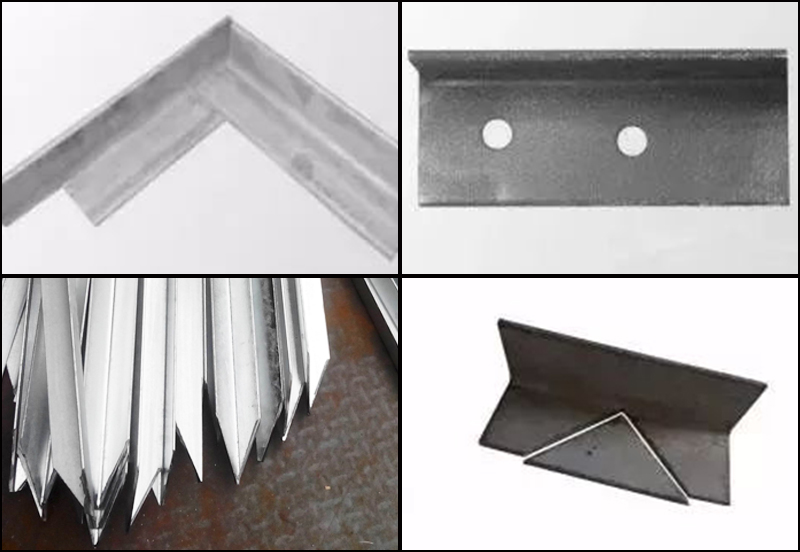

1.Cut off the angle steel

The most common method is to cut the angle steel as needed, which can be directly used with an angle steel cutting machine. There are now new vertical angle steel cutting machines that it is easy and convenient to dispense the material without the worker having to bend over.

2.Perform a 90 degree bending treatment on the angle steel

This type of equipment is also commonly used in the process of using angle steel, and can be processed using an angle steel bending machine. There are two forms of internal bending and external bending, and generally this type of equipment is hydraulic.

3. Perform 360 degree arc bending on angle steel

This type of angle steel rolling machine can be used for processing, commonly known as angle steel flange machine. Angle steel flange machine is used to roll carbon steel, stainless steel, non-ferrous metal profiles {angle steel, strip steel, channel steel, pipes, etc.} into diameter φ 320- φ A high-quality and cost-effective rolling device for 6000mm circular rings and flanges. Angle steel can be processed by internal bending and external bending, and this equipment is generally hydraulic.

4. Perform corner cutting and punching treatment on angle steel

If these processing techniques need to be implemented, it is generally recommended to use a combined punching and shearing machine, which can cut, punch, cut corners, and cut edges on angle steel. The operation is simple and convenient, and different molds need to be prepared to achieve different functions. In addition, changing the mold can also process other profiles such as flat steel, channel steel, and I-beam.

If you need angle steel or other steel products, you can find Yangtze Steel.