Seamless steel pipes / Precision steel pipes -5 commonly used heat treatment processes

What are the five commonly used heat treatment processes for steel pipes, seamless steel pipes, and precision steel pipes? There are many types of steel pipes, and the steel grades (types) used are also different. The chemical composition of steel pipes of the same variety may also have certain differences, but after heat treatment, the steel pipes can all meet the relevant technical requirements.

There are five main types of heat treatment processes for steel pipes:

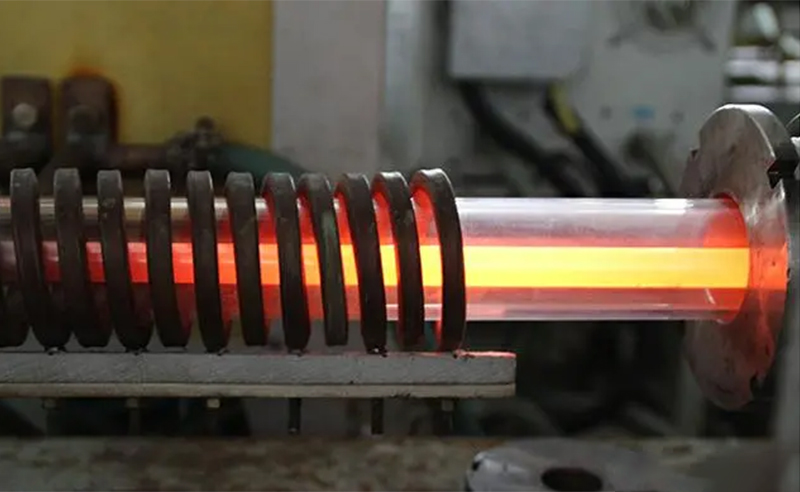

1. Quenching+high-temperature tempering (also known as quenching and tempering treatment)

Heat the steel pipe to the quenching temperature to change the internal structure of the steel pipe into austenite, and then rapidly cool it at a rate greater than the critical quenching rate to change the internal structure of the steel pipe into martensite, and then cooperate with high-temperature tempering to finally change the structure of the steel pipe into uniform tempered sorbite.

This process can not only improve the strength and hardness of steel pipes, but also organically combine the strength, plasticity, and toughness of steel pipes.

2. Normalization (also known as normalization)

A heat treatment process in which the steel pipe is heated to the normalizing temperature to completely transform the internal structure of the steel pipe into austenitic structure, and then cooled with air as the medium. After normalizing, different metal structures can be obtained, such as pearlite, bainite, martensite or their mixed structures.

This process can not only refine grain size, uniform composition, eliminate stress, but also improve the hardness and cutting performance of steel pipes.

3. Normalizing+tempering

After heating the steel pipe to the normalizing temperature, the internal structure of the steel pipe is completely transformed into austenitic structure, cooled in air, and then combined with a tempering process. The steel pipe structure is tempered ferrite+pearlite, or ferrite+bainite, or tempered bainite, or tempered martensite, or tempered sorbite.

This process can stabilize the internal structure of steel pipes, improve their plasticity and toughness.

4. Annealing

A heat treatment process in which steel pipes are heated to annealing temperature and held for a certain period of time, and then slowly cooled to a certain temperature in the furnace before being discharged for cooling.

The function of this process is:

① Reduce the hardness of steel pipes and improve their plasticity to facilitate subsequent cutting or cold deformation processing;

② Refine grain size, eliminate structural defects, homogenize internal structure and composition, improve the performance of steel pipes or prepare for subsequent processes;

③ Eliminate the internal stress of the steel pipe to prevent deformation or cracking.

5. Solid solution treatment

Heat the steel pipe to the solid solution temperature to fully and uniformly dissolve carbides and various alloy elements in austenite, and then rapidly cool to prevent the precipitation of carbon and alloy elements in time, thus obtaining a single austenite structure heat treatment process.

The function of this process is:

① The internal organization and composition of uniform steel pipes;

② Eliminate hardening during processing to facilitate subsequent cold deformation processing;

③ Restore the corrosion resistance of stainless steel.