How to Assess the Quality of Polyurethane Insulated Pipes?

The quality of polyurethane insulated pipes directly impacts the safety, energy efficiency, and service life of the entire piping system. During actual procurement and acceptance processes, comprehensive evaluation must be conducted across multiple dimensions, including appearance, performance, compatibility, and manufacturer qualifications. This article systematically introduces a practical set of quality assessment methods.

1. Visual Inspection

The outer casing of high-quality polyurethane insulated pipes should feature a smooth, flat surface free of noticeable scratches, cracks, bubbles, or wrinkles. When touched by hand, it should feel smooth without any roughness. The casing color should be uniformly consistent with no color variation within the same batch. The surface must bear clear, permanent markings indicating specifications, model, manufacturer, and applicable standards—crucial elements for product traceability.

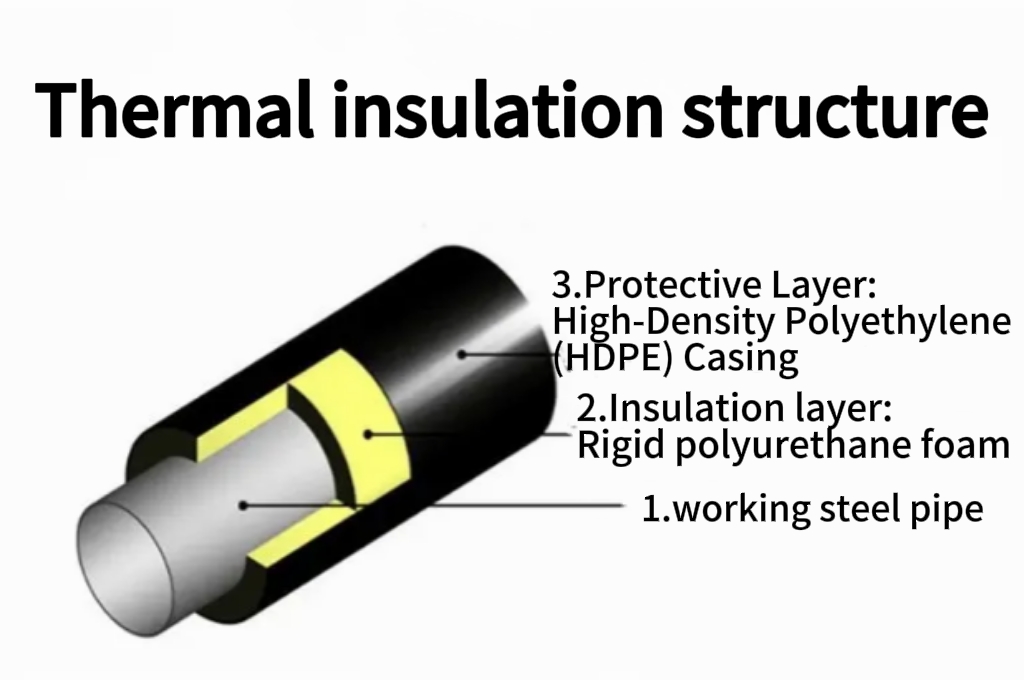

The quality of the insulation layer can also be preliminarily assessed visually. By examining the cut cross-section of the pipe, the polyurethane foam should be observed to uniformly and densely envelop the working steel pipe. It should exhibit a consistent light yellow color, with fine pores and a high closed-cell rate. The foam should tightly adhere to both the inner and outer pipe walls, showing no visible gaps, delamination, or signs of porosity.

2. Physical Performance Testing

Dimensional accuracy is fundamental. Measure the outer diameter, wall thickness, and dimensions of the working pipe using specialized tools to ensure compliance with design tolerances. Simultaneously, inspect the straightness of the pipe body, as excessive deviation can complicate installation.

Thermal insulation performance is central. Thermal conductivity serves as the key metric for evaluating insulation effectiveness; a high-quality polyurethane insulation layer should exhibit a thermal conductivity below 0.024 W/(m·K). Furthermore, use a thickness gauge to verify that the actual insulation layer thickness meets design specifications. Insufficient or excessive thickness will compromise final performance.

Mechanical properties determine durability. Insulated pipes must possess sufficient compressive strength to withstand soil pressure after burial, along with excellent impact resistance to endure external forces during transportation and installation. These properties can be evaluated through specialized pressure testing and drop-weight impact tests.

3. Chemical Performance Testing

Corrosion resistance is paramount. High-quality high-density polyethylene (HDPE) outer casings must effectively withstand chemical erosion from soil and groundwater. Working pipes typically require anti-corrosion treatment, with material composition and coating quality verified through relevant test reports.

Aging resistance determines service life. Insulated pipes must withstand prolonged exposure to environmental factors like sunlight and temperature fluctuations without significant performance degradation. Assessing whether products have undergone accelerated aging tests while maintaining stable performance is key to evaluating their long-term reliability.

4. Installation Compatibility Check

Prior to installation, inspect the connection points of the insulated pipes. Whether welded or flanged, joints must be flush and precise to ensure on-site sealing integrity and installation convenience. Additionally, verify that the piping system incorporates adequate expansion joints to accommodate thermal expansion and contraction.

5. Manufacturer Qualification Review

Finally, the supplier's qualifications and reputation are indispensable soft indicators. Verifying whether the manufacturer possesses comprehensive quality management system certifications (such as ISO9001) and relevant production licenses, while examining their past project cases and market reputation, provides greater assurance for long-term cooperation reliability than simple price comparisons.

Selecting polyurethane insulated pipes is a highly technical decision. Through the systematic inspection and evaluation outlined above, you can maximize the assurance of procuring products with reliable quality and superior performance. As a professional supplier, Yangtze Steel remains committed to providing customers with products meeting the highest standards and comprehensive technical support, ensuring the smooth implementation and long-term stable operation of every project.