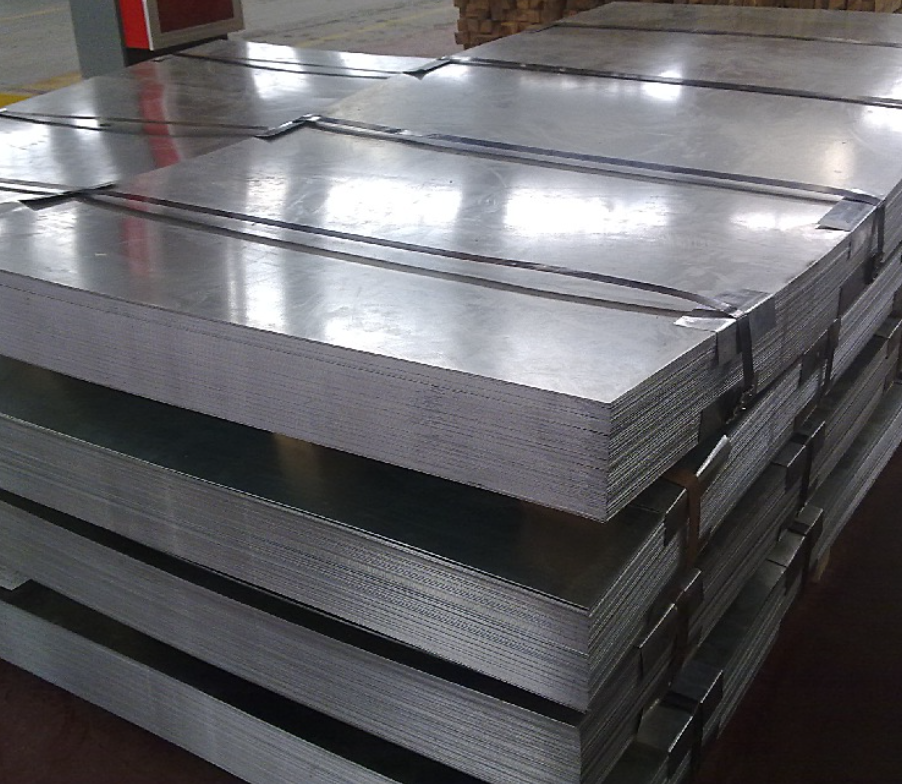

Cold-Rolled Hot-Dip Galvanized Steel Sheet: Properties and Applications

Cold-rolled hot-dip galvanized steel sheet is a metal material that combines excellent mechanical properties with outstanding corrosion resistance, finding widespread use in construction, home appliances, automotive, and other industries. This article provides an in-depth overview of its production process, core characteristics, and key selection criteria to help you gain a comprehensive understanding of this important material.

Production Process

The manufacturing process for cold-rolled hot-dip galvanized steel sheets primarily involves these key stages:

Cold Rolling: Processing hot-rolled coil to target thickness through cold rolling, ensuring the substrate achieves optimal surface finish and dimensional accuracy.

Pre-treatment: Thoroughly removing surface contaminants via degreasing and pickling to create ideal conditions for galvanization.

Hot-Dip Galvanizing: Pre-treated steel sheets are immersed in molten zinc at 450°C-465°C to form a metallurgically bonded zinc coating.

Post-Treatment: Processes including air knife control, alloying treatment, and passivation further enhance product performance.

Core Characteristics

Exceptional Corrosion Resistance: The zinc coating effectively isolates the substrate from corrosive media, offering a service life of 10-20 years in standard environments

Superior Formability: The base material exhibits excellent ductility and strength, supporting various forming processes like stamping and bending

Outstanding Surface Quality: The smooth, flat surface is suitable for direct use or further processing such as color coating

Environmentally Sustainable: Fully recyclable material aligns with circular economy principles

Primary Applications

Construction Industry: Roofing and exterior wall systems, steel structures, light steel framing, etc.

Home Appliance Manufacturing: Outer casings and internal structural components for refrigerators, washing machines, air conditioners, etc.

Automotive Industry: Body panels, chassis components, and other areas requiring high rust resistance

Other Fields: Storage equipment, ventilation ducts, agricultural machinery, etc.

Selection Guide

When selecting cold-rolled hot-dip galvanized steel sheets, focus on the following key factors:

Zinc Coating Weight: Choose an appropriate zinc coating thickness (e.g., Z60-Z275) based on the application environment.

Base Material Properties: Determine the suitable steel grade and mechanical properties according to processing requirements.

Surface Treatment: Select different surface treatments such as passivation or oil coating as needed.

Specification Matching: Accurately select parameters like sheet thickness and width to ensure compliance with project requirements

Maintenance and Care

While the product inherently offers excellent corrosion resistance, proper maintenance can further extend its service life:

Avoid surface scratches during installation

Conduct regular inspections and promptly address localized damage

Keep surfaces clean to prevent prolonged exposure to corrosive substances

Frequently Asked Questions

Q: What is the difference between hot-dip galvanizing and electrogalvanizing?

A: Hot-dip galvanizing produces a thicker coating (typically 30-200μm) with superior protection; electrogalvanizing yields a thinner coating (3-20μm) with a smoother surface, suitable for applications requiring higher dimensional accuracy.

Q: How can material lifespan be estimated?

A: Under standard atmospheric conditions, hot-dip galvanized sheets can last over 15 years with normal use. Actual lifespan depends on environmental corrosion levels, zinc coating thickness, and usage conditions.

As a professional steel trading supplier, we offer cold-rolled hot-dip galvanized sheets in various specifications. Custom zinc coating thicknesses and surface treatments are available upon request. Contact us anytime for detailed product information and technical support.