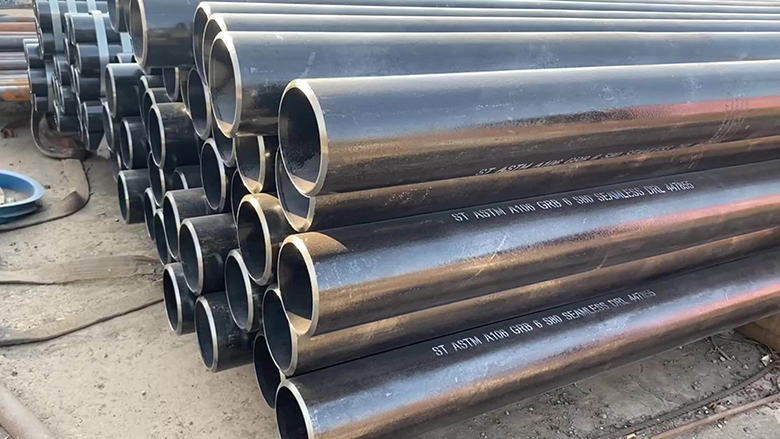

Schedule 40 Carbon Steel Pipe

Schedule 40 is a standard term for pipe wall thickness, usually referred to as SCH 40, defined according to ANSI/ASME B36.10M standard. It indicates a medium-walled steel pipe with good pressure bearing capacity and durability.

Grades of Schedule 40 Carbon Steel Pipe

Standard | Scope of application | Implementation Standards |

ASTM A53 | General fluid transportation and mechanical use | ASME B36.10M |

ASTM A106 | High temperature and high pressure fluid transportation | ASME B36.10M |

API 5L | Long distance transportation of oil and natural gas | ISO 3183 |

Dimensions of Schedule 40 Carbon Steel Pipe

Nominal diameter (NPS) | Outer diameter(OD) | Wall thickness (mm) | Inner diameter (ID) | Theoretical weight (kg/m) |

1/2" | 21.3 mm | 2.77 mm | 15.76 mm | 1.27 kg/m |

1" | 33.4 mm | 3.38 mm | 26.64 mm | 2.52 kg/m |

2" | 60.3 mm | 3.91 mm | 52.48 mm | 5.45 kg/m |

4" | 114.3 mm | 6.02 mm | 102.26 mm | 14.98 kg/m |

6" | 168.3 mm | 7.11 mm | 154.08 mm | 27.98 kg/m |

Mechanical Properties of Schedule 40 Carbon Steel Pipe

According to ASTM A53/A106 standard, its mechanical properties are as follows:

Performance Indicators | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

Minimum | ≥ 415 | ≥ 240 | ≥ 20 |

Applications of Schedule 40 Carbon Steel Pipe

1.Transmission Pipeline: Used for the transportation of water, steam, gas and petroleum products.

2.Building Structure: Used as building steel frame and support column.

3.Machinery Manufacturing: Used to manufacture parts or mechanical structures.

When selecting Schedule 40 carbon steel pipe, the size, material and surface treatment requirements should be determined according to the specific application needs. At the same time, ensure that the supplier's products meet industry standards (such as ASTM A53, ASTM A106 or API 5L) to ensure product quality and engineering safety.