Advantages of hot-dip galvanized channel steel

Hot-dip galvanized channel steel uses ordinary channel steel as the base material. After rust removal, it is immersed in zinc liquid that melts at about 440~460C, so that a zinc layer is attached to the surface of the channel stee...

2024-01-16

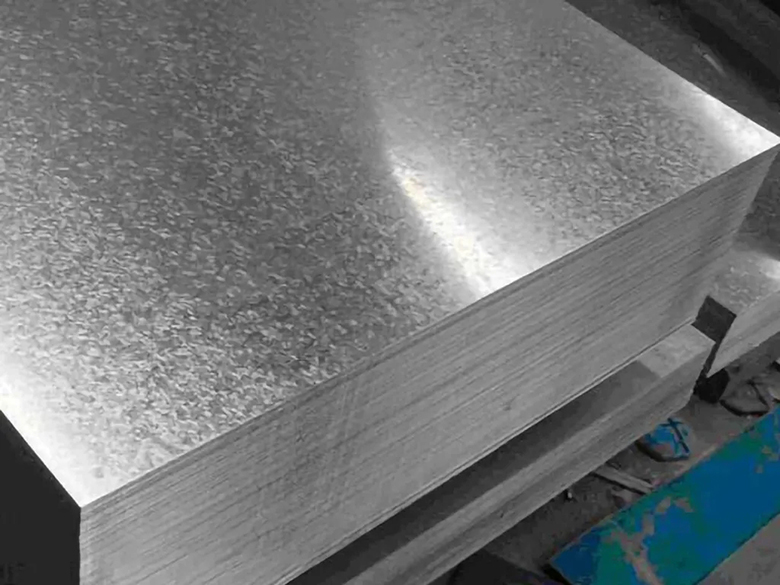

Today’s steel knowledge - galvanized sheet

Galvanized sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective anti-rust method that is often used. About half of the world's zinc production is used in this pro...

2024-01-16

Product features of galvanized square tube

Galvanized square tube is a general term for square pipe fittings and square pipes, which are pipes with the same circumference. Hot rolled strip is rolled through technical processing.Product features1. Strong anti-corrosion perf...

2024-01-15

Today’s steel knowledge – seamless steel pipe

Seamless steel pipes are made from a single piece of metal and have no seams on the surface.Product features:1. Small tolerance and high precision. High surface quality, good finish and uniform wall thickness.2. Seamless steel pip...

2024-01-15

Advantages of anti-corrosion steel pipes

Anti-corrosion steel pipes refer to steel pipes that have been processed with anti-corrosion technology to effectively prevent or slow down chemical reactions and corrosion during transportation and use. Corresponding anti-corrosi...

2024-01-12

Detailed explanation of hot rolled steel coils

Hot-rolled steel coil is a steel plate or steel coil product that is heated to a high temperature and then processed into a steel plate or steel coil product of the required thickness and width through a rolling process.Hot rollin...

2024-01-12